Nuclear Safety: GRS Participation in International Fire Related Research Activities for Nuclear Installations

Knowledge about the origin, propagation and suppression of fires is essential for assessing fire safety of nuclear installations. For this reason, GRS is continuously participating in fire related international research activities carried out under the auspices of the OECD Nuclear Energy Agency (NEA).

The NEA is an intergovernmental agency under the framework of the Organisation for Economic Co-operation and Development (OECD) facilitating the cooperation among countries with advanced nuclear technology infrastructure to achieve excellence in nuclear safety, technology, science, related environmental and economic matters, and law. The NEA has eight standing committees, two of which directly relate to nuclear power plant safety: the CNRA - Committee on Nuclear Regulatory Activities – and the CSNI - Committee on the Safety of Nuclear Installations.

The CSNI is an international committee made up of senior scientists and engineers with broad responsibilities for safety technology and research programmes, as well as representatives from regulatory authorities. Its purpose is to foster international co-operation in nuclear safety among NEA member countries. The main tasks of the CSNI are to exchange technical information and to promote collaboration between research, development, engineering and regulatory organisations, to review operating experience and the state of knowledge on selected topics of nuclear safety technology and safety assessment, to initiate and conduct programmes to overcome discrepancies, develop improvements and reach consensus on technical issues; and to promote the co-ordination of work that serves to maintain competence in nuclear safety matters, including the establishment of joint undertakings.

A variety of projects – experimental ones as well as database projects – are being carried out in order to achieve the goals of CSNI. GRS as the institution officially representing Germany in the CSNI has so far participated in all these projects sponsored by theFederal Germany Ministry of Economics and Energy (BMWi): The GRS Technical Director General is the actual CSNI Vice Chair.

One of the ongoing fire related OECD/NEA projects is the project High Energy Arcing Faults (HEAF), which is meanwhile in its second phase.

HEAF: High Energy Arcing Faults at Electrical Switchgears and Busbars Resulting in Ensuing Fires

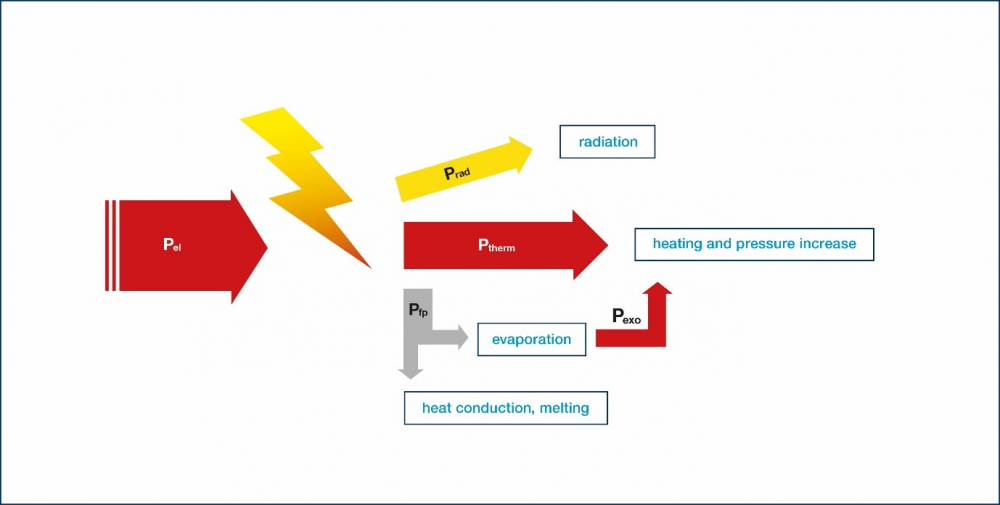

Operating experience from nuclear installations has clearly demonstrated that switchgears, breakers, load centers and bus bars and/or ducts (typically with nominal voltages of typically 380 V and above) can be subject to a unique failure mode that causes extensive damage, which may affect nuclear safety. In particular, these types of high energy electrical devices are subject to a failure mode known as high energy arcing fault (HEAF). This failure mode causes a rapid release of electrical energy in the form of heat of up to 10,000 °C, vaporized metals (e.g., copper and aluminum), plasma, and explosive mechanical force (see also Figure 1).

HEAF in electrical equipment are principally initiated in one of three ways: poor physical connection between the switchgear and the holding rack, environmental conditions or the introduction of a conductive foreign object (e.g., a tool used during maintenance). A high energy fault scenario typically consists of two distinct phases, each with its own damage characteristics. The first phase is characterized by the short, a rapid release of electrical energy from the arc of typically 100 cal/m2, which may result in a catastrophic failure of the electrical enclosure, the ejection of hot projectiles from damaged electrical components or housing and/or fire(s) due to the extremely high temperatures. Such fires may only involve the electrical device itself or any external combustibles exposed. The second phase, i.e., the ensuing fire typically includes ignition of combustible material within the HEAF zone of influence (ZOI).

Observations from the international operating experience of nuclear installations collected in the OECD/NEA Database FIRE (Fire Incidents Records Exchange) have indicated that HEAF of medium and high voltage (0.4 to 12 kV) electric breakers can induce ensuing fires and may deteriorate fire barrier elements.

This was a major reason that – under the auspices of the OECD/NEA – a first HEAF experimental series has taken place in the more recent past underpinning the observations from the operating experience. In conclusion, fire hazard analysis (FHA) as well as Fire PSA should therefore adequately consider such events in assessing the safety of NPPs. Moreover, regulatory guidance addressing HEAF and HEAF induced fires is needed.

For gaining further insights in more realistic HEAF events and consequential fire scenarios in nuclear power plants, a follow-on project, HEAF Phase 2 of a former activity on HEAF induced fire has been recently started.

HEAF, Phase 2 Experiments Supported by Regulators from Germany and the Netherlands

The ongoing OECD/NEA second phase of the experimental project HEAF 2, is aiming on further insights in more realistic HEAF events and consequential fire scenarios in nuclear power plants. The corresponding test plan of the OECD/NEA experiments and the supplementary tests which specifically cover the situation in U.S.-American nuclear power plants, reflects the HEAF efforts as a whole in two distinct parts. The OECD/NEA driven tests and the additional testing are being performed by the U.S. Nuclear Regulatory Commission (NRC) Office of Research with an enhanced focus on the phenomena associated with HEAF events in the presence of aluminum either in the component itself or as part of the enclosure. These experiments are intended to characterize thermal and pressure conditions as well as by-product deposits on surfaces created by HEAF occurring in electrical cabinets and bus ducts. The experimental results will provide qualitative information of the impact of HEAFs on typical targets in electrical rooms such as electrical cables and nearby equipment.

For the participating countries it is essential that – after the first HEAF tests series focusing on the phenomena and the possibility of generating ensuing fires by HEAF – the second phase of this international project will gain more insights on HEAF with arrangements of electrical cabinets being representative for existing NPPs.

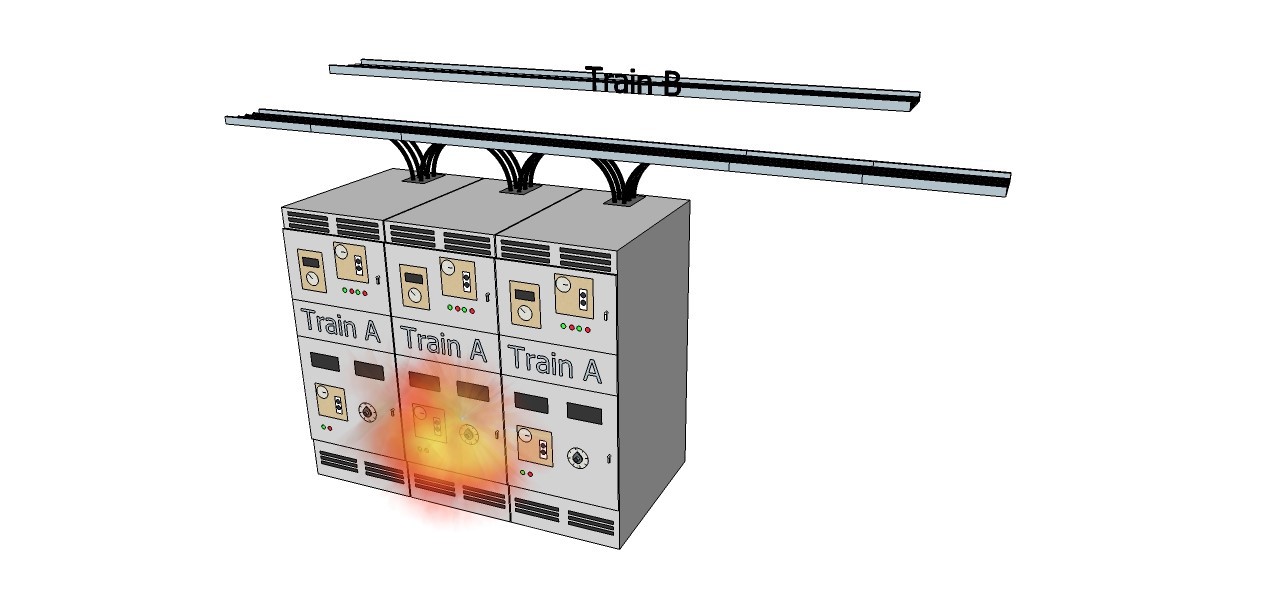

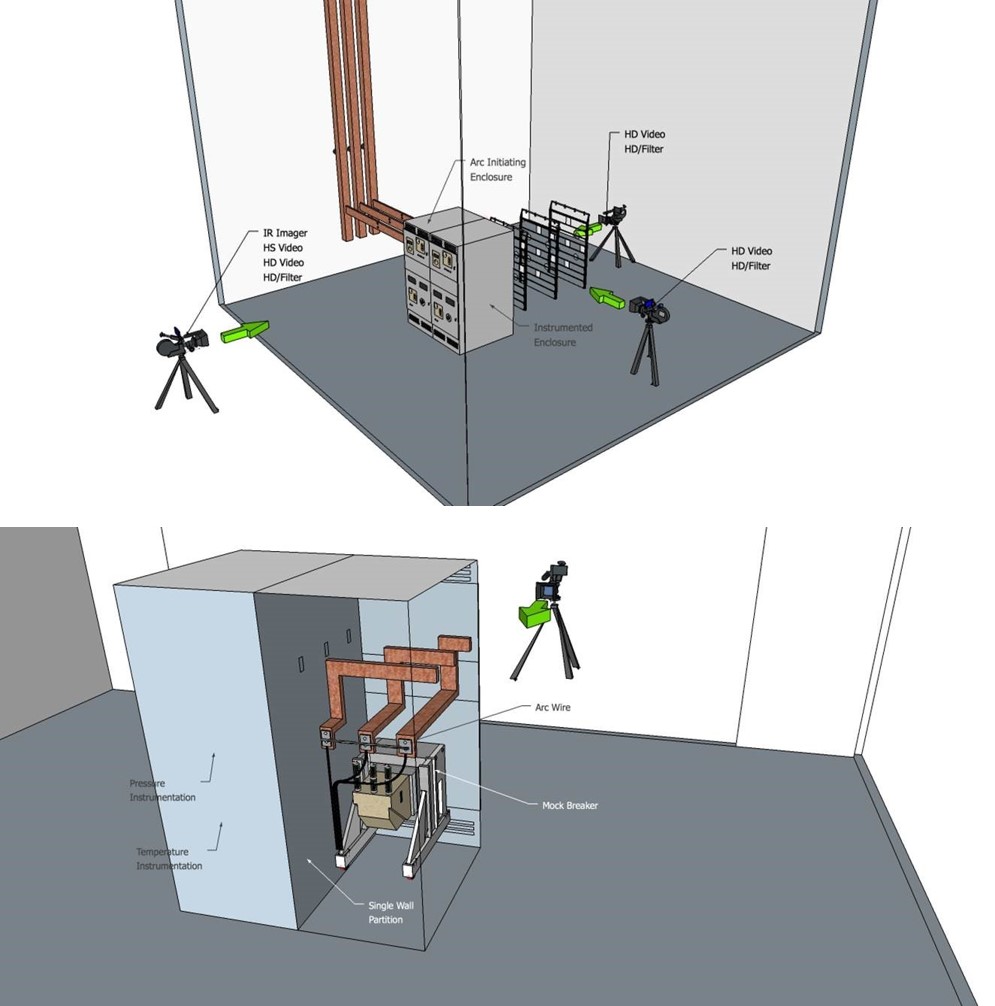

Some regulatory bodies, such as the Dutch Authority for Nuclear Safety and Radiation Protection (ANVS) or the German Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (“Bundesministerium für Umwelt, Naturschutz und nukleare Sicherheit”, BMU) are highly interested in these experiments since some comparable breakers endangered by HEAF are in operation in their existing NPPs in operation, or even under post-commercial permanent safe shutdown or decommissioning. Both countries therefore participate in the OECD/NEA HEAF 2 by providing medium and high voltage breaker cabinets for HEAF testing in an as far as practicable realistic geometry of two or more cabinets in row as outlined in Figure 2. Figure 3 shows a typical European medium voltage test enclosure configuration for the OECD/NEA HEAF 2 tests.

Major goal of the HEAF 2 experiments is to simulate more realistic scenarios typical for nuclear power plants, which are also representative for the operating experience. Therefore, there are two parts of the testing: In a first step, supplementary tests being representative for electrical breakers/bus bars and bus ducts installed in U.S. nuclear power plants, partly involving aluminum, are being tested.

In a second step, the OECD/NEA specific experiments, both with bus ducts and with bus bars/breakers in cabinet enclosures, will be tested. These also cover tests with the electrical breaker cabinets from Europe, in particular Germany and the Netherlands having donated such cabinets. These tests will be carried out as far as practicable under typical conditions with cabinets in row. Arc durations will be varied taking at least two of the three values of 2 s, 4 s, and 8 s, two different currents will be chosen from 15 kA, 25 kA, and 35 kA.

More details on the HEAF 2 experimental setup can be found in three papers from NRC, GRS and ANVS published by GRS in

Röwekamp, M., H.-P. Berg (Eds.): Proceedings of SMiRT 25, 16th International Seminar on Fire Safety in Nuclear Power Plants and Installations, October 28-30, 2019, Ottawa, ONT, Canada, GRS-A-3963, Gesellschaft für Anlagen- und Reaktorsicherheit (GRS) gGmbH, Köln, Germany, Dezember 2019, https://www.grs.de/en/publication/grs-3963.

Sven Dokter

GRS gGmbH

sven.dokter@grs.de