Full System Decontamination of the primary circuit at Doel 3 NPP: safety assessment by Bel V

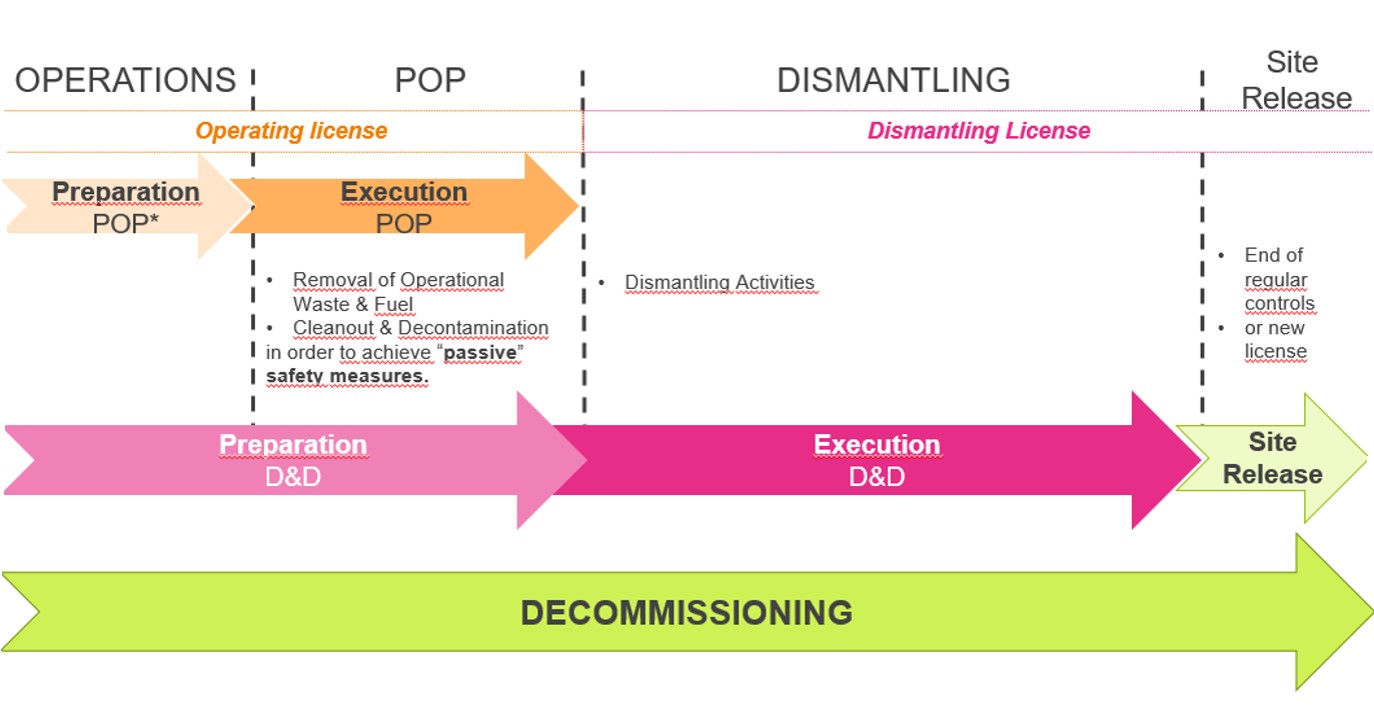

According to the law for nuclear phase out in Belgium, the third unit of the Doel NPP (referred to as “Doel 3”) was permanently shut down in September 2022 after 40 years of operation. Doel 3 entered in so-called Post Operational Phase (POP, see Figure 1), during which the licensee prepares notably its safe dismantling. Among these preparatory activities, the licensee performed a chemical Full System Decontamination (FSD) of the Doel 3 primary circuit, including several auxiliary circuits (e.g. the chemical and volume control system). This activity mainly aimed at decreasing the radiation exposure of the workers during the future dismantling activities. The preparation and the realization of the FSD was a challenge for the licensee and regulatory body (RB, composed by FANC and Bel V), notably because it was the first FSD on a PWR unit in Belgium.

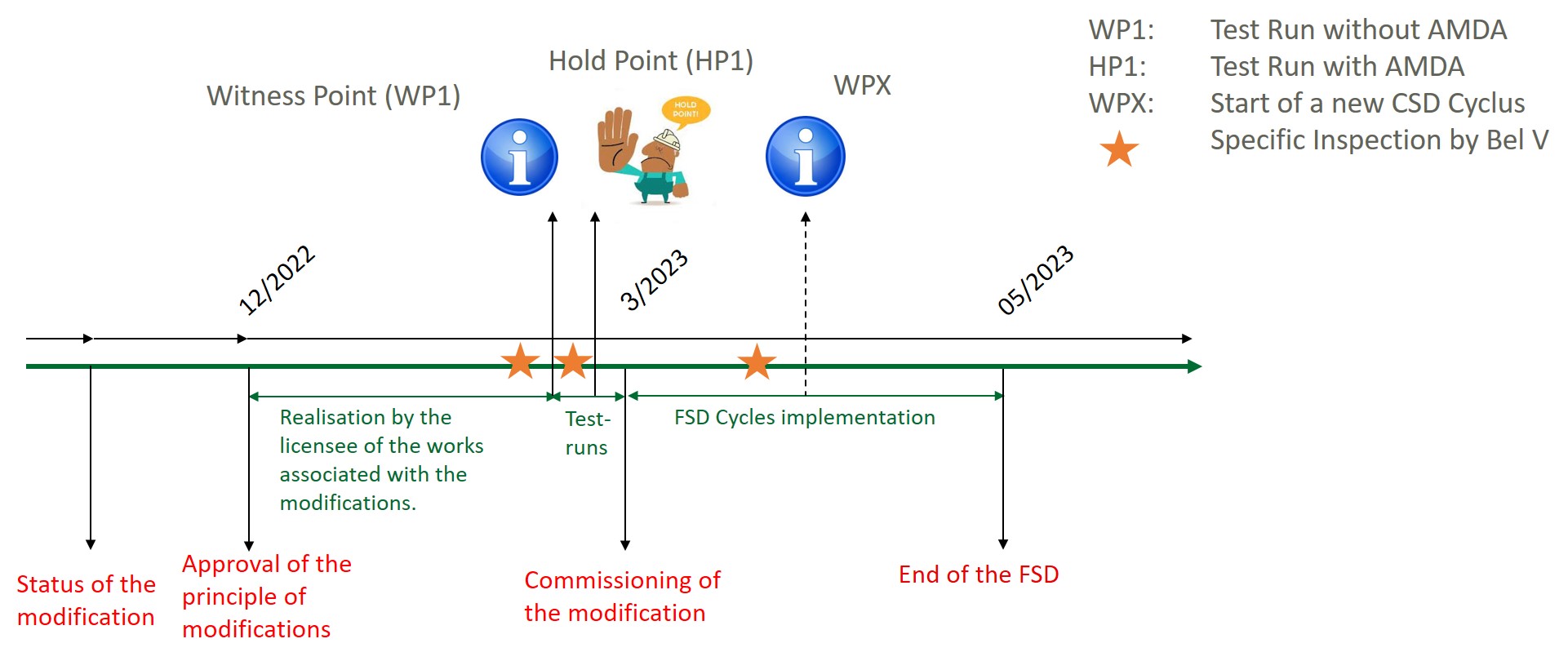

From a regulatory perspective, the FSD operation was considered as a temporary modification of the plant and the corresponding existing modification process, agreed by the licensee and the RB, was followed. The RB completed this process with relevant hold and witness points, allowing a stepwise implementation of the FSD operation (see Figure 2). The process allowed the development of constructive interactions between the licensee and the RB about the FSD preparation and implementation, as well as building trust between the main stakeholders in the feasibility and the safety of the FSD project. To guide the development of the safety assessment related to this modification process Bel V provided the licensee and its Health Physics Department with several expectations organised in 7 key topics. For instance: the justification of the FSD from the ALARA point of view, the safe management of the generated radioactive waste (on the short and longer terms) and the management of radiation protection and hazards during the FSD). They have helped the licensee to manage important issues for Bel V in a timely manner, compared to the planning of the project.

In addition to its evaluations of the safety assessments performed by the operator, Bel V performed several controls in the installations of Doel 3 to verify that the FSD was prepared and operated as agreed in the modification process and its corresponding safety assessments. For instance, before they were put into operation, Bel V controlled the conformity of the new FSD radioactive resin storage tanks with the agreed specifications. Bel V also controlled the proper implementation of several measures foreseen in the ALARA study and in the studies related to the fire risk management.

During the FSD no safety significant deviation compared to the evaluated safety assessment was noticed by Bel V. The FSD resulted in a mean Decontamination Factor of the circuits superior to 100 (exceeding the initially defined DF target of 10). Globally the volume of radioactive effluents and waste estimated in the safety assessment were conservative compared to the generated volumes and no storage issues occur. The radiological characterisation by the licensee of the generated effluents and waste is ongoing.

Stéphane Palmaerts

Bel V

stephane.palmaerts@belv.be