Successful completion of SAT tests for the Bohunice FSS project

After an unfortuate fire accident in 2020 the full scope simulator (FSS) for Bohunice NPP operated by VUJE became inoperable and had to be rebuilt in the new premises. Due to the great scope of the work the project itself was divided into two phases. In first phase finishing in 2022 VUJE delivered new hard panels, I/O system and upgraded 3rd party systems which existed in the original FSS. The aim of the ongoing second phase is to make the FSS, now the asset of Slovenske elektrarne, more representative and in line with the real control room, so the trained control room staff has all equipment and systems available the same way as in the real unit. In this second phase VUJE implemented several changes to the thermohydraulic model, delivered code for severe accident and integrated two new 3rd party systems.

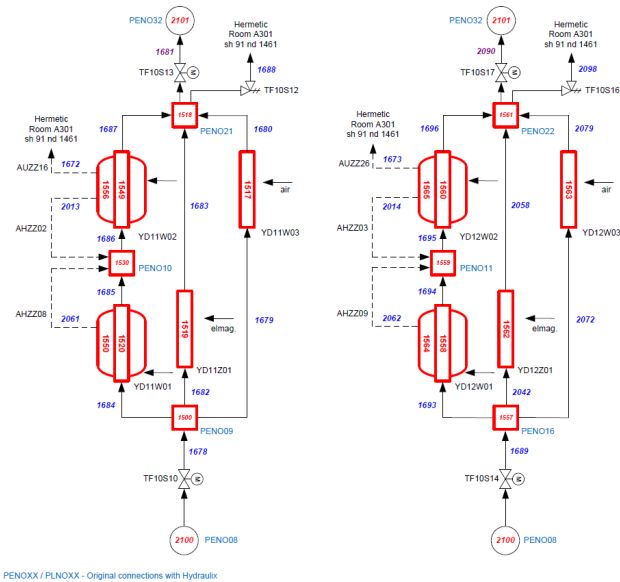

Changes in thermohydraulic model includes remodeling the leaks on the auxiliary system of the main cooling pump (MCP). The purpose of implementation of this change was to prevent a situation where a single-phase thermohydraulic code is unable to process physical parameters within the cell during transition states (water-steam). That why a part responsible for simulation of this leakage has been taken out from the single-phase and modeled in two-phase code. Now the scenario is trained without any issue.

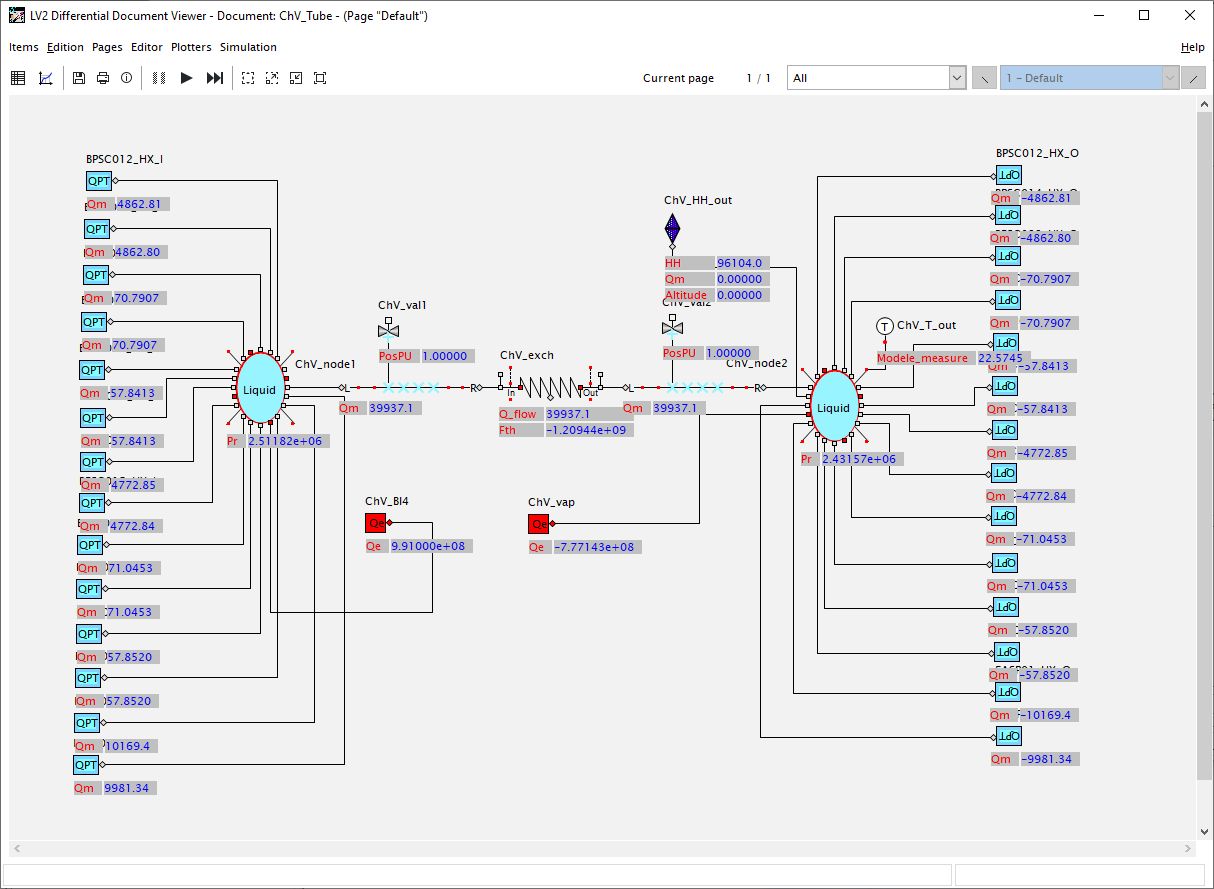

Beside that simulator development team faced an interesting challenge how to properly model the impact of the temperature of the outside air to the turbine power. The temperature of the air can impact the efficiency of a nuclear power plant's turbine power output. Warmer air is less dense than colder air, which affects the turbine's ability to manage the under pressure in the main condenser of the turbine. This can result in a slight decrease in the overall power output of the plant. VUJE developed a new thermohydraulic circuit in ALICES simulation software and added the impact of the power of the second unit as the circulation cooling circuit is common for both units.

In addition to these two above modifications VUJE with its supplier CORYS integrated Melcor code to the simulator executive, which has been described in the separate article in this link [https://www.etson.eu/node/347]. In the beginning of August 2023 VUJE successfully finished the SAT by completion of challenging scenarios for LOCA (loss of coolant accident) and SBO (station blackout).

Changes in 3rd party systems involved more than thousands of new signals for the TPS system (unit information and control system) and the delivery of two new systems which were not part of the first phase of the project.

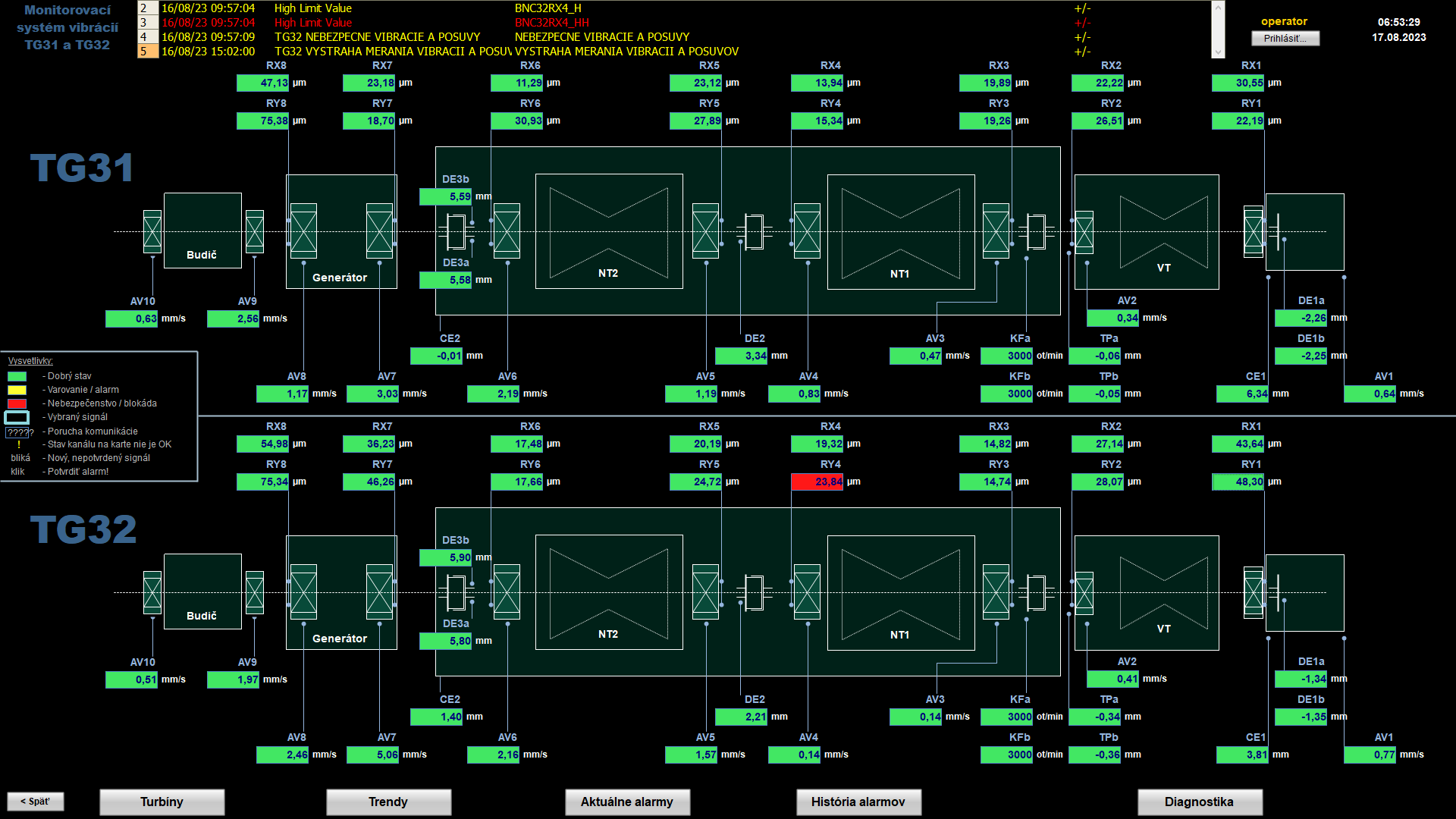

The AMS operator station in the real control room is used to display the current state of oscillation, vibrations, and displacements of the Emerson AMS 6500 ATG system on turbines. VUJE simulated such station and installed it in the simulator control room and integrated it to the model of the simulator. Simulator model now provides data on the values of vibrations and displacements of turbogenerators necessary for reliable operation of turbogenerators based on the data provided by Slovenske elektrarne.

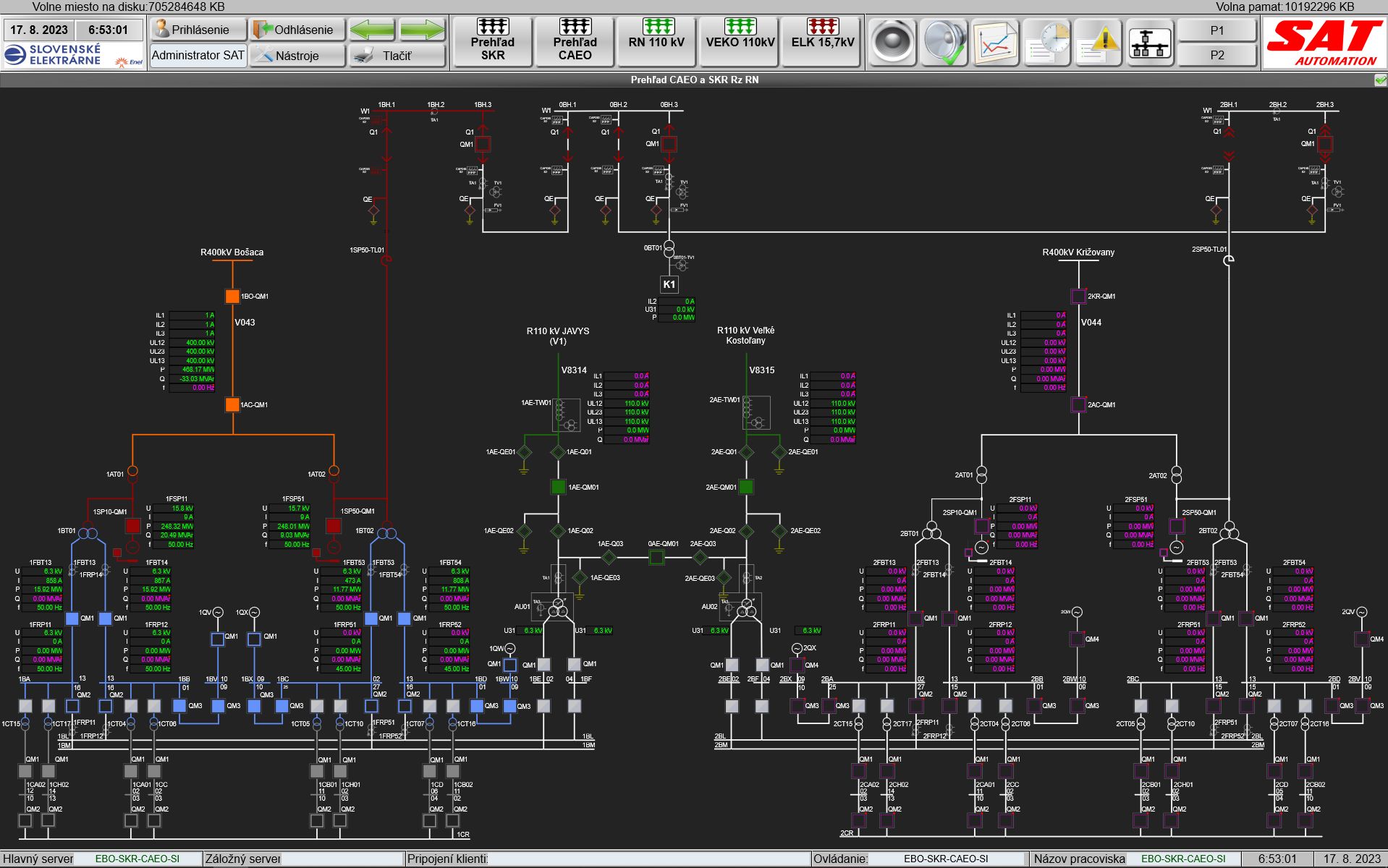

Further VUJE and its subcontractor implemented RIS (control information system) operator station which is used by shift electrician engineer to control the unit electric distribution. RIS operator station is built based on SCADA (Supervisory control and data acquisition) software and represents the last evolution of this system in the plant and is connected to the simulator electrical model.

Simulators for nuclear power plants are continuously evolving to improve safety, training, and operational efficiency. Bohunice simulator provides an environment that replicates the behavior of a real nuclear power plant, allowing operators and personnel to practice various scenarios and responses without actual risks. Over time, simulator development has progressed from basic models to advanced, high-fidelity systems. Overall, the constant development of nuclear power plant simulators aims to enhance operational safety, improve operator training, and refine plant efficiency, contributing to the safe and reliable generation of nuclear power.

Notes:

Link to the article about Melcor: https://www.etson.eu/node/347

Juraj Marec

VUJE, a. s.

juraj.marec@vuje.sk