Preliminary Analysis Focusing on In-Vessel Thermal Hydraulics in Loss-of-Heat Removal Systems in a Sodium-Cooled Fast Reactor

Generally, Loss-Of-Heat Removal System (LOHRS) is one of the Beyond Design Basis Events (BDBEs) of a Sodium-cooled Fast Reactor (SFR) and is assumed to result from the successful shutdown of the core and the loss of the decay heat removal capability due to piping failure at the primary heat transport system and air coolers, among other things. To simulate this event more appropriately, the Nuclear Regulation Authority has improved an in-house severe accident simulation code, AZORES. Since AZORES development has been focused on models of core melt progression and ex-vessel phenomena regarding Level 2 probabilistic risk assessment, AZORES adopts simple cooling system analytical models. In LOHRS analysis, however, precisely simulating the thermal-hydraulic behavior and plant response affects the accident sequence outcome. Thus, the study aims to enhance the capability of in-vessel thermal hydraulics simulation in AZORES by coupling a plant dynamics simulation code for SFR, ADYTUM. The simulation results using this coupling method will provide technical knowledge regarding not only phenomena challenging the failure of the fuel pin, reactor vessel, and containment vessel but also confirmation of the effectiveness of countermeasures during LOHRS for regulatory activity. As the first step of the code development, a preliminary analysis was conducted to confirm the in-vessel thermal hydraulics contributing to core melt progression in Loss-Of-Heat Sink (LOHS) event.

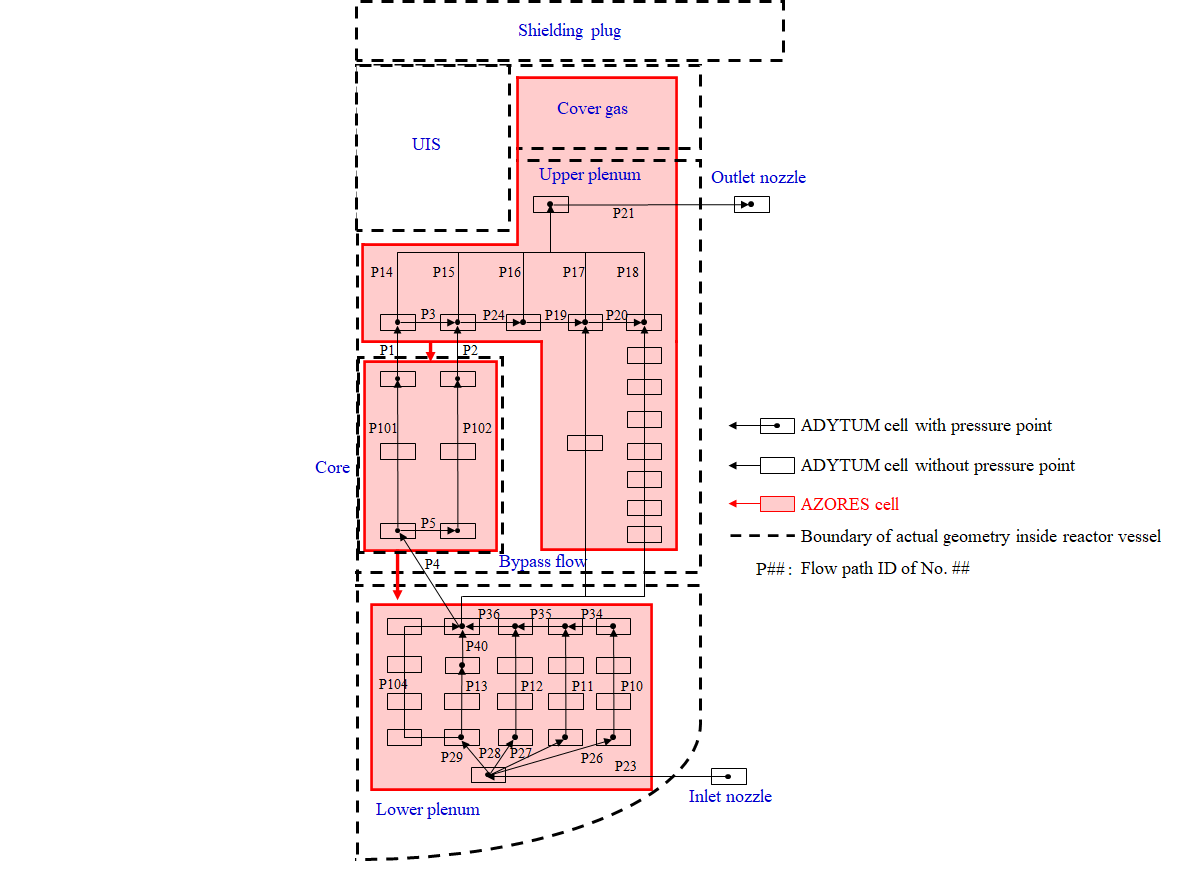

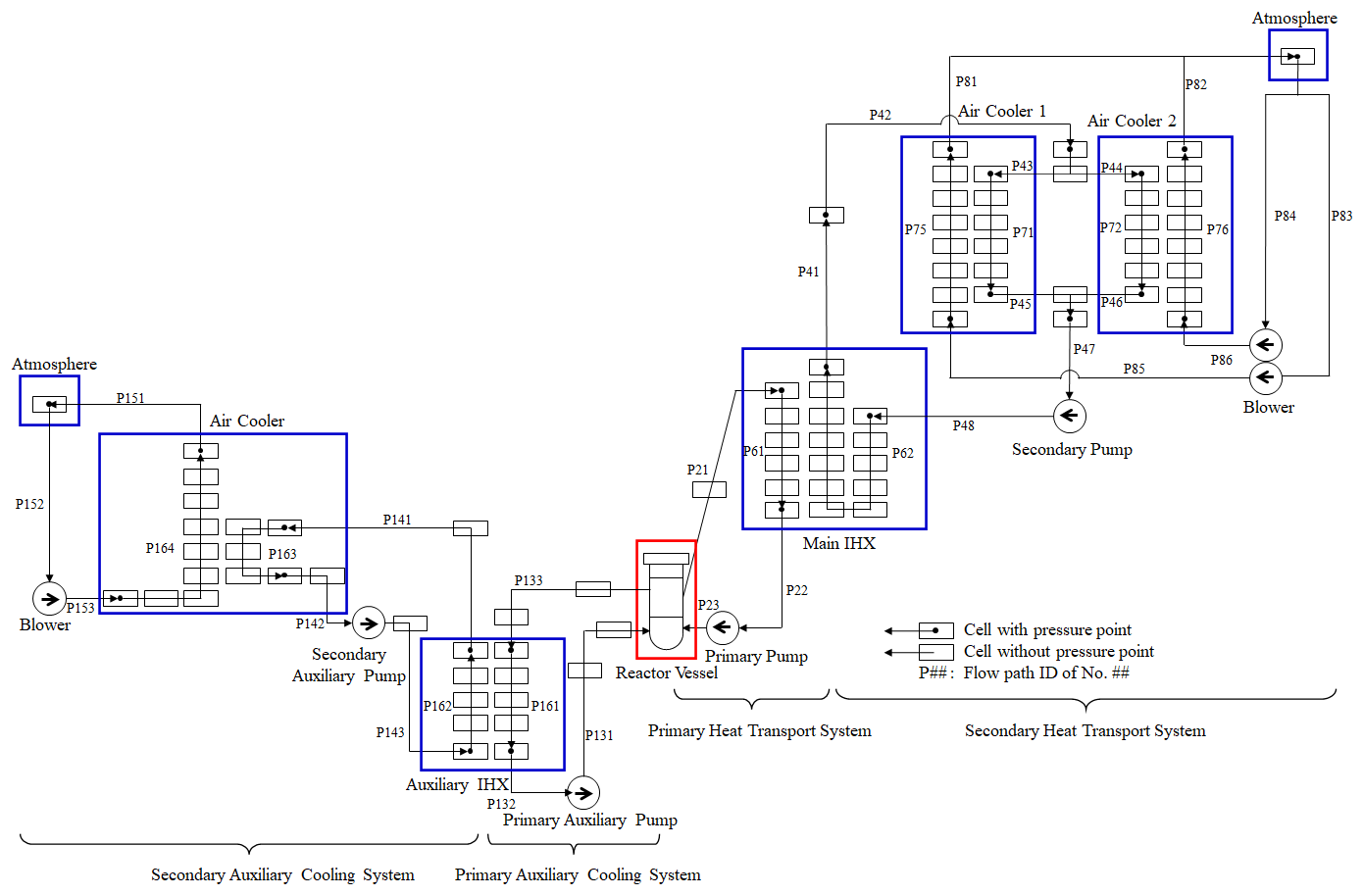

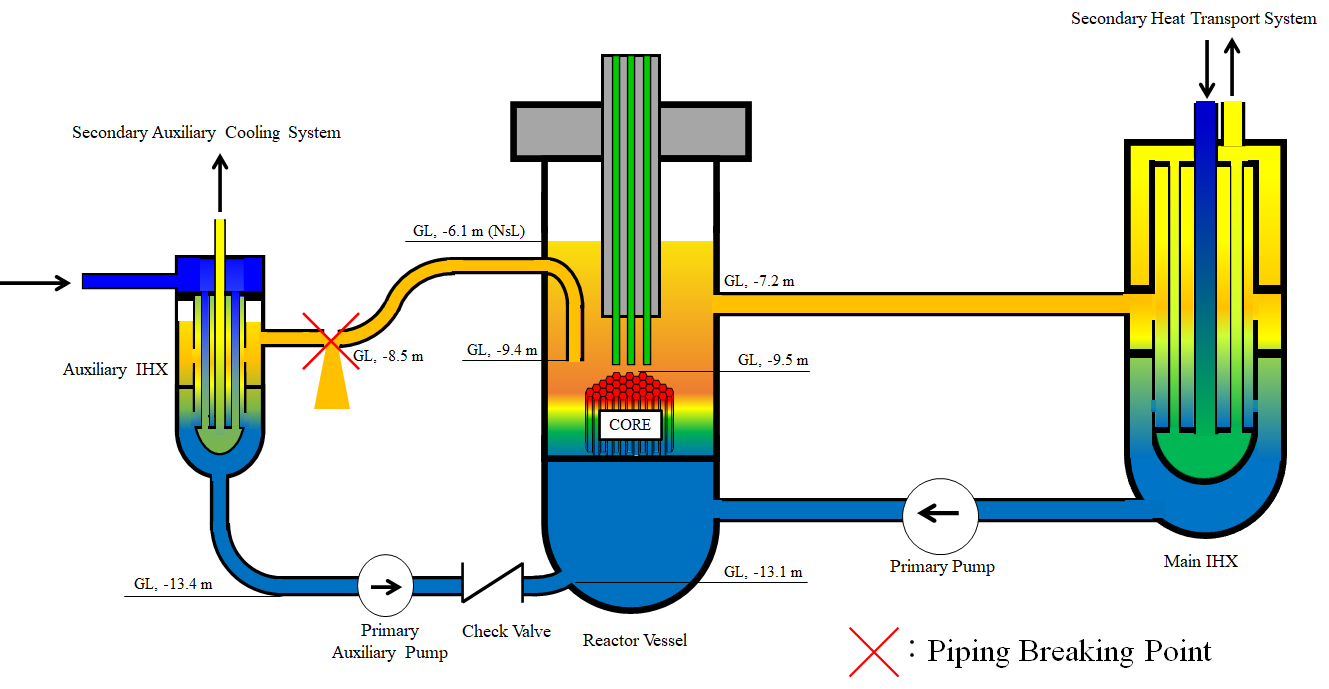

LOHS is a BDBE categorized to a LOHRS scenario where the core is successfully shut down, but the ultimate heat sink is lost. The analysis target of this study was LOHS at a typical experimental-class SFR shown in Figures 1 and 2. In this analysis, it was assumed that sodium leak was caused by the double-ended guillotine of the primary auxiliary cooling system’s piping shown in Figure 3. To verify the coupling method, a single calculation using only AZORES was also conducted.

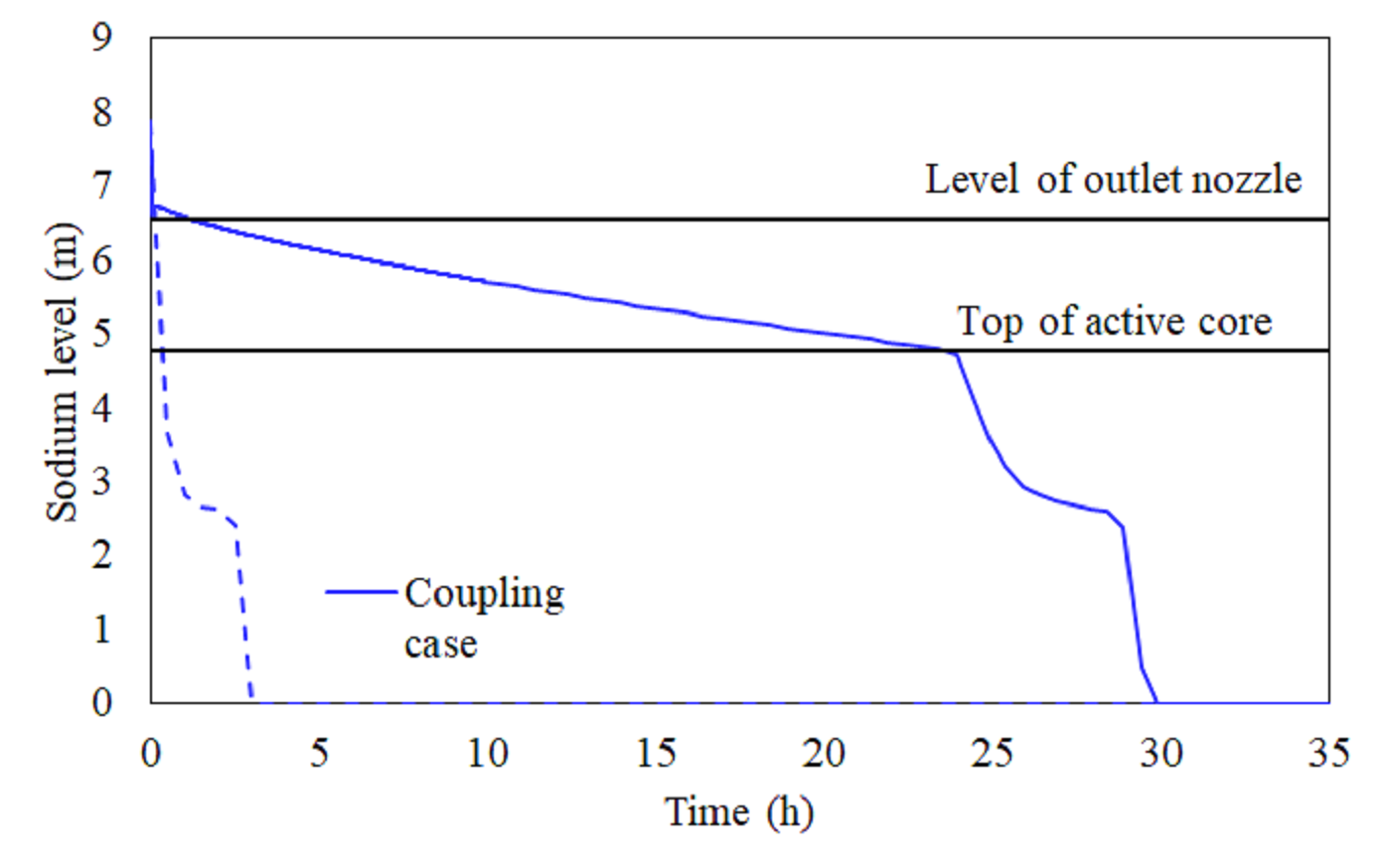

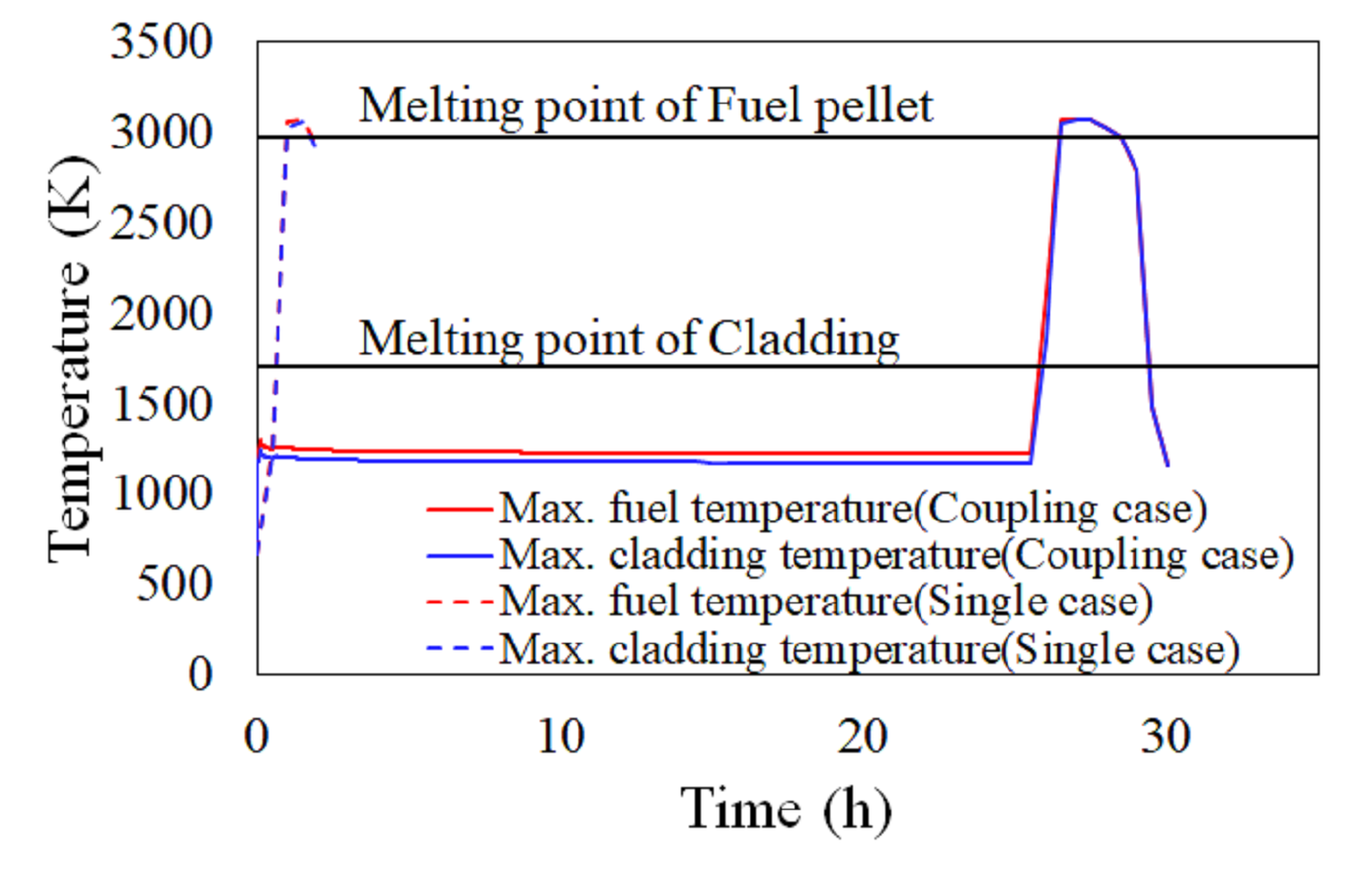

In Figure 4, based on the comparison between the coupling and single cases in the LOHS analysis, the time taken for the sodium level to fall below the height of the outlet nozzle was identified as being significantly different. Since the coupling case takes 28.5 h until the core is uncovered, that is, approximately 15 times that of the single case, the decay heat level significantly decreases compared to the single case. Thus, the core melt progression in the coupling case is slower than in the single case. After the core was uncovered, the capability of heat removal from fuel was already lost. Therefore, in Figure. 5, the temperatures of the fuel pellet and cladding increase at an accelerated rate. The current model of ADYTUM-AZORES assumes that molten steel moves accompanied by molten fuel. This assumption imposes the constraint that the molten materials should be in thermal equilibrium though the melting temperature of steel is lower than that of UO2, as shown in Figure. 5. In future work, the analytical model related to core melt progression will be improved and a verified addition to the thermal hydraulics model for highly realistic simulations.

Click on image to open and enlarge.

References

[1] H. Sonoda, et al., “Preliminary analysis focusing on in-vessel thermal hydraulics in loss-of-heat removal systems in a sodium-cooled fast reactor”, Annals of Nuclear Energy, Vol. 192 (2023), 109992.

Hiroki Sonoda

Nuclear Regulation Authority (NRA)

sonoda_hiroki_8id@nra.go.jp