Presence of foreign material in the primary circuit of BR2

Introduction of the BR2

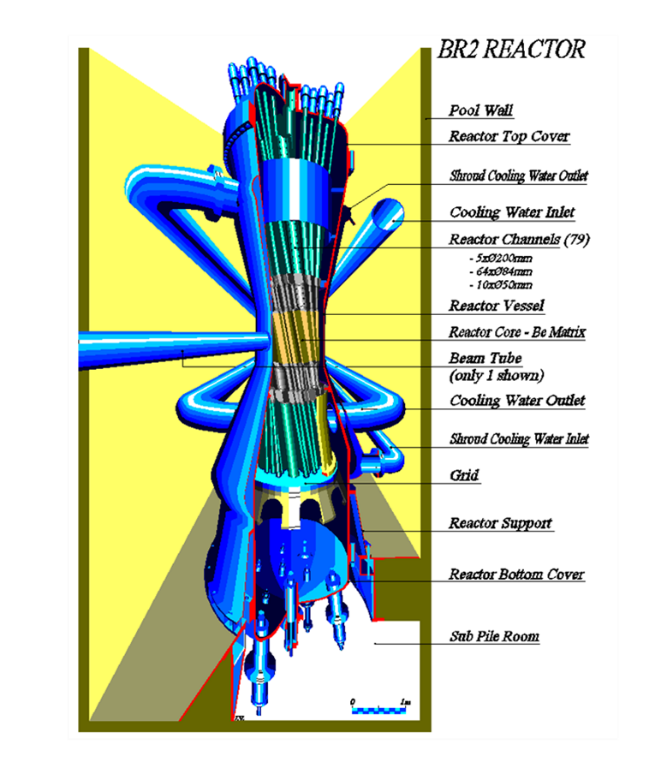

The BR2 Material Test Reactor, owned and operated by the Belgian Nuclear Research Center (SCK CEN) located in Mol, is a heterogeneous, High-Flux thermal reactor with a maximum thermal power of 125 MW. The cylindrical fuel elements contain highly enriched uranium. The BR2 is cooled by light water in a closed, pressurized loop operating at 1.2 MPa with an opened secondary loop and modular cooling towers. BR2 is an important tool for the production of radioisotopes for medical and industrial applications and for the irradiation (doping) of silicon intended for the microelectronics industry. In addition, BR2 tests fuels and materials for various reactor types and in the framework of the European nuclear fusion program. These tests contribute to ensure the safety of current and future nuclear facilities.

|

|

Recently experienced event

On 11/10/2022, at the end of the irradiation cycle 05/2022A the reactor was stopped, as planned. After shutting down the primary pumps, the operator observed that one of the main primary pumps was running backwards. The Licensee suspected a counterflow through the check valve located after those primary pumps and he decided to carry out a reactive maintenance on the same day.

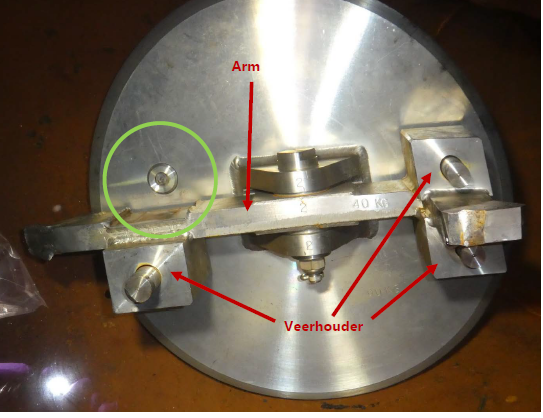

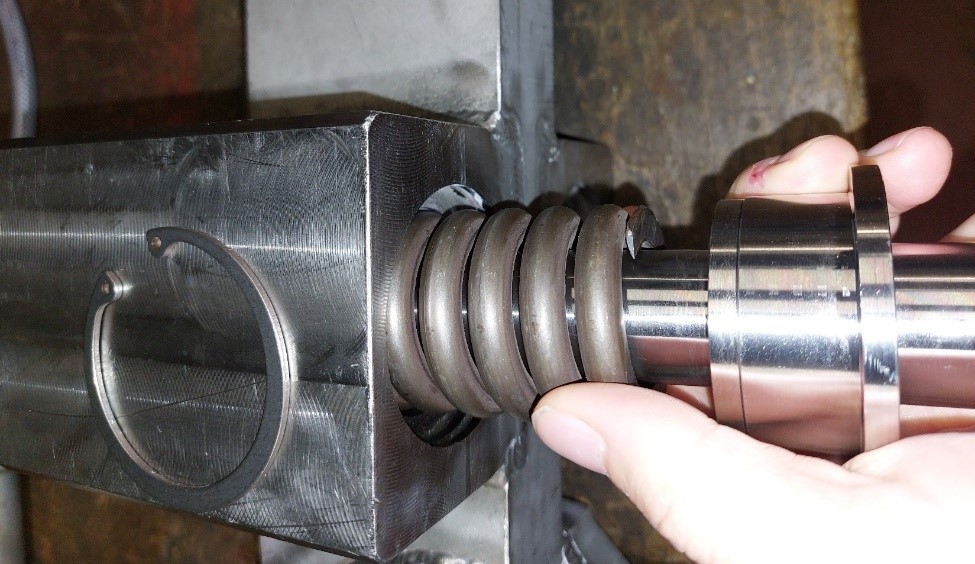

On 13/10/2022, upon opening the check valve, the Licensee noticed that several welds at the valve were broken, causing one of the parts (i.e. one spring retainer of the arm of the check valve) to end up in the primary circuit. This broken part consists of a stainless steel piece, which dimensions are 70x90x127mm³, which weight is about 6.5 kg, and that is composed of 5 different pieces held together.

The absence of the spring holder in the check valve shows that the spring holder has been carried away by the primary water flow delivered by the primary pump. Indeed, with the high primary cooling flow rate of the BR2, the primary water can carry away objects quite easily.

The spring holder most likely did not break down when the reactor was stopped on 11/10/2022, but before, during the cycle 05/2022.A or even during a preceding cycle. During this period, there were no observations of components or instrumentation that would have been damaged by the presence or passage of the spring holder. A possible indication is a loud noise reported during the cycle 01/2022.

The reason why a component of the check valve broke has been investigated and the investigation of the fracture does confirm a fatigue mechanism.

The operator has conducted several investigations to locate the foreign object, without success until now. A detailed hydraulic model of the interaction between the flow and the object has been established and the conclusions of the model are coherent with the observations of absence of the object in the inspected parts of the primary loop upstream the reactor core (including the upper part of the reactor vessel). The model predicts that an object of the size of the missing component would indeed stay on the bypass valve and subsequently drop in the part of the primary loop downstream of the reactor during a shut-down. This part is not readily accessible for inspection.

The broken check valve was replaced. In the aftermath, the operator submitted to the authorities a request for derogation, with a detailed risk analysis, to restart the reactor with a foreign material within the primary circuit. The risk analysis demonstrated that the impairment of a control rod, the blockage of the fuel cooling or a leak in the primary circuit were very unlikely. Furthermore, the first signs of occurrence of these events would be rapidly detected.

Therefore, the safety authorities have granted the derogation for a restart of the reactor limited to 2 cycles but did require a number of compensatory measures to reduce the residual risks. The safety authorities imposed an enhanced monitoring during the operation of the reactor (periodic verification of the movement of the control rods, monitoring of the primary pump behavior, periodic reporting of the primary leak rate and activity in the primary and secondary circuits, immediate notification in case of deviations…). In addition, the safety authorities required a feasibility study to localize and retrieve the object in the primary circuit and to prevent the occurrence of a similar event in the future by improving the design of the check valves.

BR2 was restarted and successfully completed the 2 irradiation cycles 07/2022A and 01/2023. At this moment, BR2 is in shutdown as planned and the safety authorities will investigate if the conditions are fulfilled to safely restart the reactor.

|

|

Nicolas Noterman

Bel V

nicolas.noterman@belv.be