NACIE-UP CRP on transition form forced to natural circulation

A coordinated research project (CRP) has been proposed to IAEA to perform a numerical benchmark on experimental data. The name of the CRP is ‘Transition from forced to natural circulation experiment with heavy liquid metal loop’ and started officially in July 2022.

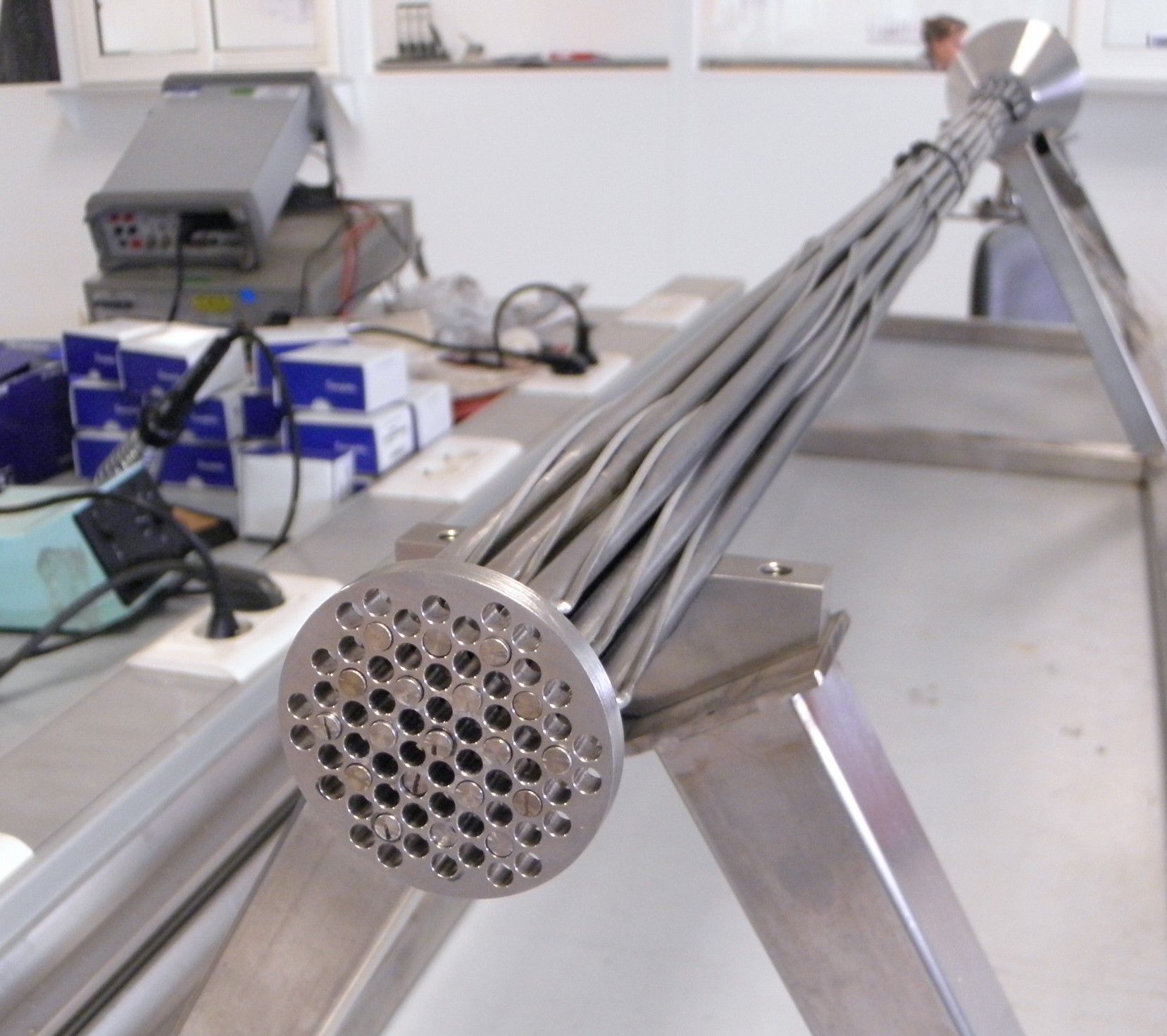

The numerical benchmark exercise will be executed based on the experimental data provided by ENEA. The experimental platform involved is NACIE-UP (NAtural CIrculation Experiment UPgrade, see Figure 1), a loop-type facility using Lead-Bismuth Eutectic (LBE) as primary coolant, located at the ENEA Brasimone Research Centre in Italy. The facility consists of a rectangular loop hosting a Fuel Pin Bundle Simulator (FPBS) with 19 electrical heaters, with a total maximum power of 250 kW (see Figure 2). The pins are wire-wrapped in a hexagonal lattice with 3 ranks of subchannels and are well instrumented.

The facility can work both in forced circulation regime and natural circulation regime thanks to the difference in height between the heat source and the heat sink of about 5 meters.

The secondary loop works with pressurized water (16 bar) and it is thermally coupled with the primary loop by a double-wall heat-exchanger with stainless steel powder in the gap. Finally, the power is transferred to the environment through an air-cooler.

The tests consist of steady state and transient conditions. The tests provide both local (on the FPBS) and overall (on the loop) data for comparison with numerical analysis. The mass flow rate is measured by an innovative thermal mass flow meter. Therefore, different type of codes can be validated with a comparison with experimental data.

The experiments consist of a uniform test with all the pins active and two non-uniform tests with some pins switched off. The first part of the benchmark activity will be open based on published data and all the data on the selected cases will be shared with the partners. The second part will be semi-blind on a selected case and the last part will be a post-test analysis with the complete set of data delivered to the partners for final comparison.

The numerical activities will be carried out using a system STH code, a sub-channel code, CFD codes, and coupled CFD/STH codes to exploit the multiscale nature of the phenomena involved in the system. The STH code will simulate all the transients of the experimental tests, while sub-channel and CFD codes will simulate the steady state conditions at the beginning and at the end of the transients. The coupled tool will be adopted for simulating the transient experimental tests around the transition from forced to natural circulation. All the codes will be used for the open phase, the semi-blind phase and for the post-test analysis of the provided experimental data.

For the development of Gen-IV Heavy Liquid Metal (HLM) technology, the code validation is one of the main tasks to be addressed. This benchmark has the explicit goal of validating different multiscale codes in the context of HLM technology. Then, after validation, codes can be used to simulate similar situations in a real reactor.

The numerical benchmark will be carried out by 26 partners (see Figure 3 for a picture of kick-off meeting in Brasimone) from all over the world and will assess the capability of reproducing local and global experimental data in the case of transition from forced to natural circulation regime in heavy liquid metal facilities.

Ivan Di Piazza

ENEA

ivan.dipiazza@enea.it