Award by the Technology Agency of the Czech Republic

SÚRO v.v.i. together with ÚJV Řež, a.s. and Centrum výzkumu Řež s.r.o. received from the Technology Agency of the Czech Republic (TAČR) the TAČR 2021 Award in the category "GOVERNANCE" for the project "Computational model for thermomechanical behaviour of a fuel rod with the inclusion of degradation processes of nuclear fuel coverage" (TRANSURANUS Project), solved within the TAČR Théta research programme. The Technology Agency of the Czech Republic is an organizational unit of the state that was founded in 2009 for the support of research, experimental development and innovation.

The aim of the project was to develop a computational model for the thermomechanical behaviour of nuclear fuel in normal operation and accident conditions of NPPs with the TRANSURANUS code, including the effects of secondary cladding degradation, within a two-year period on the basis of available correlations and experimental data, and to evaluate to what extent the existing methods for deriving the so-called acceptance criteria for nuclear fuel correspond to the current state of knowledge in this field.

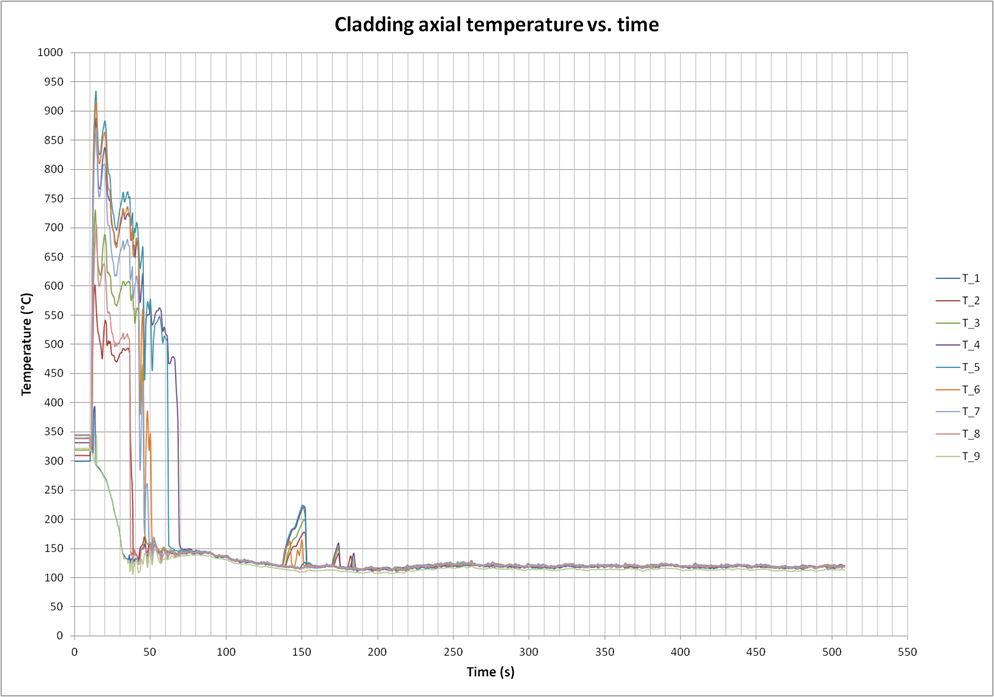

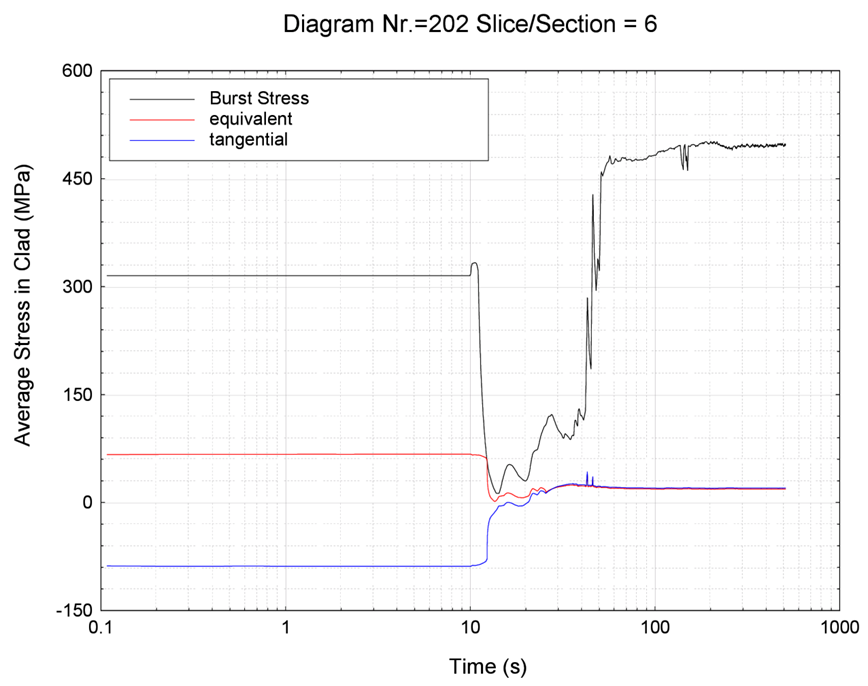

In the frame of the TRANSURANUS project, it was assessed the thermo-mechanical performance of a new proposed Westinghouse fuel with an improved performance for the Czech NPPs. The main goal of the analysis was to consider the consequences for the fuel integrity of a couple of possible accidental transients, namely pump trip (LOFA) and a pipe break (LOCA), in particular, concerning resulting stresses, strains, temperatures, cladding corrosion and damage. The input of the TRANSURANUS calculations were the data provided by thermohydraulic simulation performed preliminarily with the TRACE code, fundamentally providing the axial distribution of cladding temperatures vs. transient time (Fig. 1). The outcome of the thermo-mechanical simulation work proved that no adverse consequences occur during the worst scenario, both considering fuel pellets and cladding, also considering the combined criterion which includes the stress level and plastic instability (Fig. 2).

|

|

Part of the research activity was devoted to the comparison of two different types of cladding materials, namely Zircaloy and E-110 (Zr-1Nb), during an LB-LOCA scenario in the Temelin NPP in the high power rod. Event was hypothesized in a high LHR rod (44 kW/m) after 1 cycle; average burnup was ca 20 MWd/kgU. It was shown that the performance of the two materials considered, i.e. Zircaloy and E-110, is similar and for both safety criteria are met, although some differences in mechanical response are evident. The research also confirmed that thermomechanical analysis of the transients is beneficial and can highlight critical aspects not disclosed by traditional thermohydraulic and neutronic analyses.

In addition a comparative analysis of the Halden IFA-617 and IFA-633 Creep Tests Data Related to the M5 Cladding Material was performed. The analysis focused on two M5 cladding creep tests performed at the Halden reactor test rigs and reported in the Halden reports HWR-658 [1] and HWR-755 [2]. These two tests included fuel rods operated at different cladding stress conditions. In IFA-617 the M5 cladding operated in compressive state, i.e. the cladding inner pressure was lower than the outer pressure, whereas in IFA-663 the cladding tube was pressurized also beyond outer pressure, hence producing tensile stress conditions. The work generated conclusions on M5 cladding creep based on the obtained tests results, in particular an original physical model coherent with experimental results was formulated. The outcome of this work represents a step forward for the assessment of the TRANSURANUS code capability to simulate the creep behavior of M5 (and similar materials) cladding.

The project has enabled the creation of a knowledge environment for expert assessment of nuclear fuel safety for the needs of the government, in particular for the licensing procedures of the State Office for Nuclear Safety.

Dipl. Ing.Vincenzo Romanello, Ph.D.

SÚRO

vincenzo.romanello@suro.cz

Jitka Mikšová

SÚRO

jitka.miksova@suro.cz