Securing nuclear fuel for European research reactors

One of the biggest challenges for today's European research reactors is the sustainability of their operation and the related need to secure the supply of nuclear fuel. Two groups of research reactors are particularly affected by this challenge:

- High Performance Research Reactors (HPRRs) (reactors with higher neutron fluxes), such as the BR2 reactor at SCK SCK-CEN (Belgium), the RHF reactor at the Institut Laue-Langevin in Grenoble, the FRM II reactor at the Technical University of Munich and the JHR research reactor under construction at Cadarche (France).

- Medium Power Research Reactors (MPRRs), which are characterised by their original Soviet design and are still dependent on the monopoly fuel supplier TVEL, the Russian manufacturer: these include the LVR-15 reactor at the Research Centre Řež, the MARIA reactor at Swierk in Poland, the BRR reactor at the MTA Institute in Budapest, etc.

Recognising the importance of maintaining the operation of research reactors in the EU and the risks they face, the European Commission included in its 2016 H2020 EURATOM research programme for 2016-2017 the theme NFRP 11: EU support for securing the supply of nuclear fuel for research reactors.

A key driver for this research project was to enhance the security of supply of medical radioisotopes such as Molybdenum-99 and the availability of adequate neutron irradiation capacity in the EU for materials testing and other applications.

In response to this challenge, the operators of the four Western European research reactors, which are grouped together in the HERACLES group, together with the French Commissariat for Nuclear Energy (CEA), the French company AREVA (now split into Framatom and TechnicAtom) and the Rez Research Centre, prepared a proposal for the FOREvER (Fuel fOR REsEarch Reactors) project, which contained three strategic objectives:

- ensuring progress in the development of molybdenum-based fuel (UMo)

- verification of the possibility of an alternative fuel based on U3Si2 with a higher uranium density, so-called "high-loaded U3Si2"

- to qualify a European fuel supplier for the European MPRR dependent on TVEL fuel.

The project was approved and launched in October 2017. Its solution has two basic directions:

- for HPRR reactors, the development of UMo fuel (dispersed or monolithic type) and as an alternative high-loaded U3Si2

- for MPRR reactors, the development, production and in-service verification of a plate fuel based on standard, qualified U3Si2 (4.8 gU/cm3).

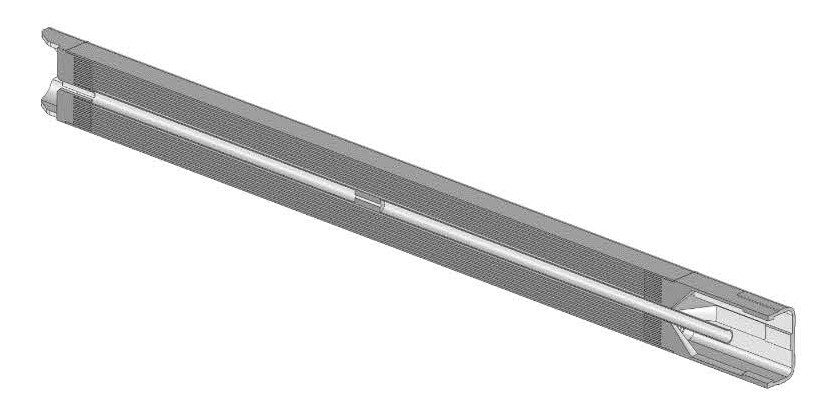

The MPRR reactors with the original Soviet design use fuel produced by the Russian company TVEL. These fuels usually have a special design (see Figure 1), which currently creates a monopoly position of the TVEL production company with all the possible consequences of such a position, such as the price of the fuel, the conditions of the supplier and also the uncertainty or non-guarantee of its supply in the long term.

The FOREVER project aims to develop a European alternative to the types of fuel currently in use. To verify the development and qualification of a new fuel based on standard U3Si2 plates, the LVR-15 research reactor was chosen in the project as the representative of several other MPRRs in Europe and also because it has a very good operating history.

As already mentioned, the LVR-15 reactor operates with Russian fuel assemblies. The design is made of aluminium alloy, the fuel itself is in the form of a dispersion of UO2 in an aluminium matrix and with an aluminium coating. The fuel elements are concentric square tubes and the reactor currently uses an eight-tube version as the standard fuel assembly and a six-tube version for the application of control rods and irradiation probes.

In the project consortium the TechnicAtome is responsible for the design of the prototype fuel assembly and the Framatom CERCA for its manufacturing. SÚRO v.v.i. was particularly involved in the verification assessment of the designed fuel associated with the licensing process for the planned irradiation test of the prototype fuel assembly. This process involved a series of thermohydraulic and neutron calculations to verify the safety of the test.

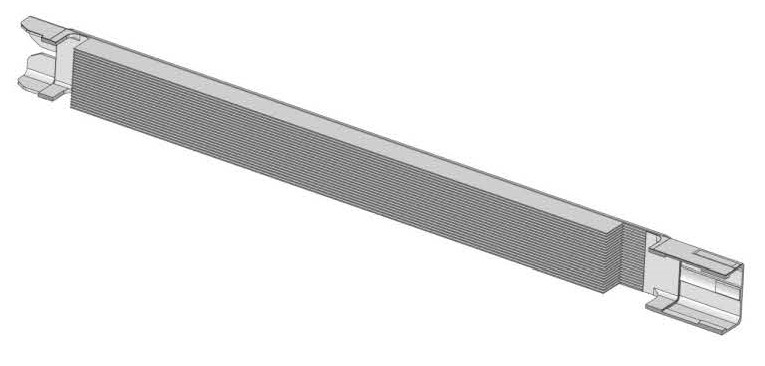

The geometry of the proposed fuel assembly is based on a fuel type with which CERCA has long term manufacturing experience. It is a plate type fuel that retains the upper and lower head geometry from the IRT-4M fuel. These heads had to be retained due to the particular geometry of the core support plate and the technology of the handling fuel assembly. The size of the plates and their total number corresponds to the required hydraulic and neutron properties. The fuel is a standard U3Si2 alloy in an aluminium matrix, the fuel plate cover is designed in aluminium alloy. The specific geometry of the assembly is shown in section for illustration on Fig. 2

A number of neutron and thermohydraulic codes were used for design and verification calculations. These include the CATHARE code, which is a thermohydraulic code developed by CEA. It was applied by TechnicAtome to determine parameters such as maximum power or fuel hydraulic characteristics that would correspond to a core constructed purely from CERCA fuel assemblies. On the Czech side, the SERPENT code, which is a three-dimensional neutron code based on the Monte Carlo method, and the NODER code, which was developed for neutron calculations of the LVR-15 reactor core, were used. In this project, both codes were used to simulate a core populated with IRT-4M fuel assemblies and one CERCA fuel assembly. For thermo-hydraulic calculations, the RELAP code was used for the same configuration. The Ansys Fluent CFD code was also applied for hydraulic analysis of the designed assembly, creation of axial pressure drop profile and for comparison of the characteristics with IRT-4M.

The licensing process of the prototype French fuel assembly was completed by a decision of the SUJB issued on the December 21, 2021, which allowed the irradiation experiment to be carried out in the core of the LVR-15 reactor. The assembly was loaded into the reactor on March 10 and will undergo a several-month trial operation, which will be evaluated by a visual post–irradiation inspection at the end.

Miroslav Hrehor

SÚRO

miroslav.hrehor@suro.cz

Jitka Mikšová

SÚRO

jitka.miksova@suro.cz