Cosmic particles allow X-ray vision

GRS experts develop computational code that can be used to simulate muon radiographic images in order to test the suitability of the method for examining storage casks for spent fuel assemblies.

In Germany, a repository for high-level radioactive waste will not be available for several decades. Until then, the waste, which also includes spent fuel assemblies from the operation of nuclear power plants, will have to be stored in dedicated storage facilities. As things stand today, however, the waste will remain in these storage facilities for considerably longer than the originally estimated 40 years, which is why, among other things, additional proof of the safety of the waste casks and their inventory is required.

In this context, GRS experts are dealing with the question of which methods are suitable to gain knowledge about the condition of the inventory inside the storage cask. Within the scope of a research project, they have now developed a calculation code that can be used to simulate muon radiographic images. The experts have tested to what extent the method is suitable for examining storage casks.

Monitoring of casks in the storage facility

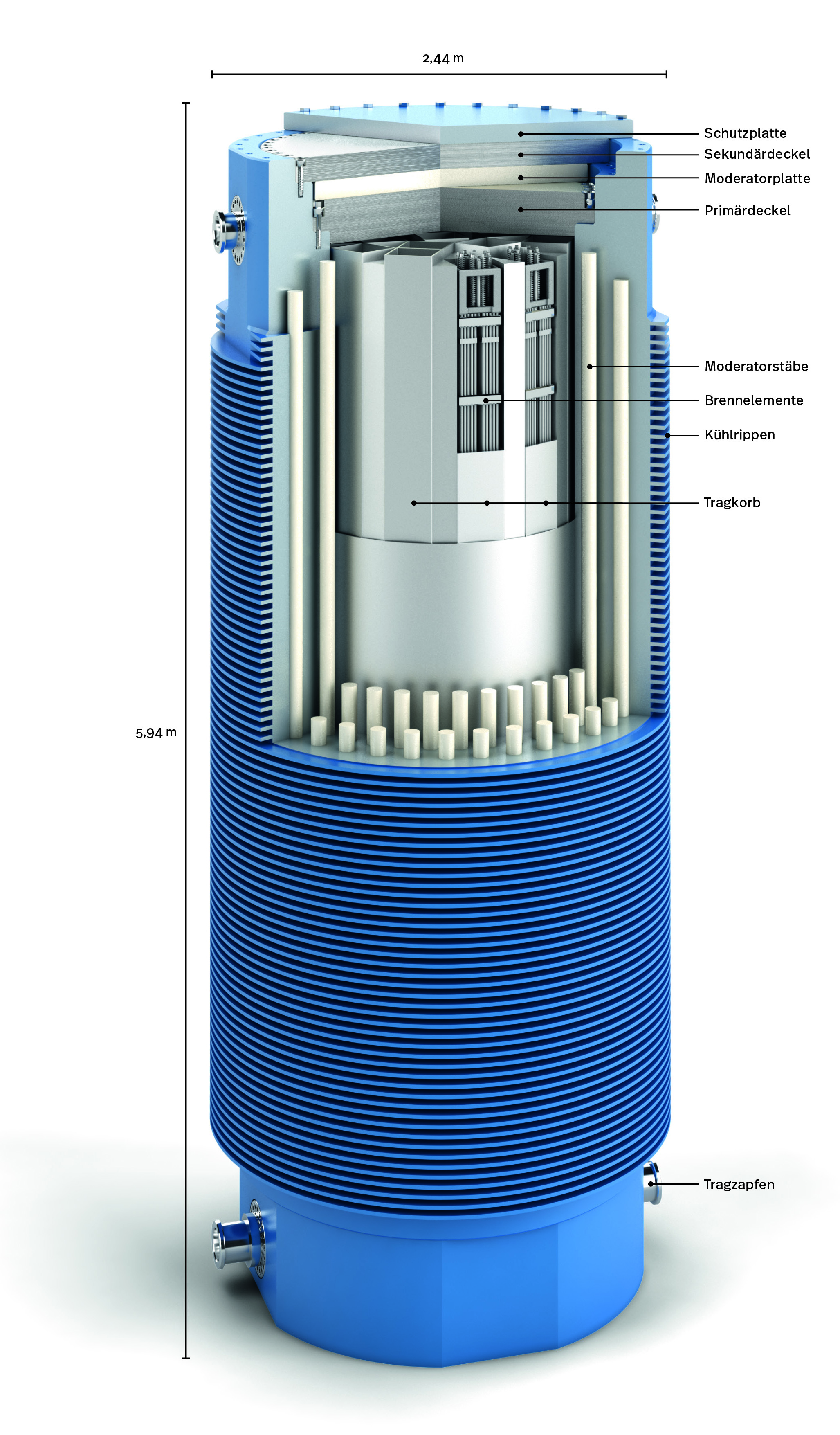

All casks in a storage facility are continuously monitored. On the one hand, this is done in the form of visual inspections, during which obvious damage to or corrosion on the containers can be detected. In addition, the storage casks are connected to a monitoring system that measures the pressure in the helium-filled inter-lid space between the primary and secondary lids (see Figure 1).

If there is a drop in pressure (e.g. due to a damaged seal on one of the lids), the monitoring system triggers an alarm. However, insights into the condition of the inventory inside a storage cask cannot be derived by means of these (measuring) methods.

Even if it seems obvious at first, opening a storage cask as part of a routine inspection is currently out of the question: the technically complex cask system would have to be opened under shielding in a so-called hot cell with remote-controlled tools due to the high radiation emitted by the inventory.

Methods for examining the inventory

So how can information on the condition of the inventory be obtained, especially with regard to prolonged storage? And how best to do this without having to open the cask? Researchers worldwide are addressing these and similar questions both in experimental studies and with the help of simulation calculations.

Experience values from experimental studies are available, for example, from the so-called three-dimensional temperature field measurement and antineutrino monitoring. However, both methods require detailed knowledge of the fuel history - including questions about the period of use or the operation of the reactor - which is why they are considered less suitable for assessing individual storage casks. Conventional radiography with neutrons or photons has so far not yielded the desired results either - partly due to the large dimensions of the storage cask and the thick metal walls (for dimensions, see Figure 1).

Researchers are currently hoping for more success when it comes to non-invasive control and monitoring of the interior of storage casks with so-called muon radiography. The principle is comparable to an X-ray image, except that it can be used on a larger scale.

Muons are short-lived elementary particles and a component of cosmic radiation. They are available at all times without any further aids and do not lead to any additional radiological burdens. Another advantage is that they can also penetrate heavy matter, such as uranium. The higher the density of the matter into which the muons penetrate, the more muons are absorbed in this matter (à transmission probability) and the greater the angle at which the muons are deflected (à scattering angle). Both quantities, i.e. the transmission probability and the scattering power, can be used for imaging purposes. In an experimental, true-to-scale setup, the muons are detected with large-area detectors placed on two opposite sides of the object to be measured. For each individual muon, it can be determined whether it has possibly been completely decelerated (absorbed) in the object itself. If necessary, the effective scattering angle can also be determined.

Using muons for imaging is nothing new in nuclear technology: among other things, the method was used in the course of the clean-up work at the destroyed Fukushima nuclear power plant. Here, muon tomography (which allows three-dimensional images compared to muon radiography) was used to locate the molten fuel in Reactors 1 and 2 from the outside.

GRS study: Simulation of muon radiography

Previous studies on examining the inventory of storage casks using muon radiography - both experiments and simulations - are concerned with the fuel assembly as such. As a rule, these studies used a transverse experimental set-up in which the detectors capturing the movement of the muons were placed on each of the long sides of the cask.

In a currently ongoing simulation study, the GRS scientists now want to clarify further open questions in connection with the muon radiography method and, in particular, investigate the resolution capacity, i.e. the image quality. As part of a code developed by GRS for this purpose, it is possible to simulate how particles interact with matter when penetrating it - in this case the model of a storage cask. For this purpose, cask systems and the nuclear fuels they contain were digitally modelled. The GRS researchers based their investigation on a configuration in which the detectors are arranged above and below the cask. Among other things, the researchers wanted to find out whether muon radiography can also detect individual missing fuel rods, and if so, whether there are any limitations or requirements for the experimental setup and how much time is needed for a measurement.

Results and next steps

The simulations have shown that even with simple analytical procedures, the muon radiography method is even able to detect individual missing fuel rods in the storage cask (see Figure 2). This, however, requires an extremely long measuring time of about two years.

In addition, the investigations showed the extent to which differences in the quality of the images produced occur - depending on the proportion of the initial angle distribution taken into account for imaging as well as the imaging information used (transmission probability or effective scattering angle, see Figure 3).

In future work, the researchers will therefore investigate, among other things, the extent to which better imaging algorithms and methods for reconstructing the scattering angle can reduce measuring times. In addition, the calculation method is to be validated - using experimental data - and extended e.g. to tomographic (three-dimensional) images.

Further simulations are planned i.a. with horizontally running scans and other cask geometries. In addition, the method is to be applied to other, application-related scenarios in the context of extended storage and investigations are to be carried out on the sensitivity of the calculations (at what percentage of the runs does the calculation software recognise the missing fuel rod, or similar). The research group also plans to publish the simulation code it has developed and thus make it accessible to other research institutions.

Sven Dokter

GRS

sven.dokter@grs.de