International cooperation in the development of models for severe accident analysis in VVER-1000

After the Fukushima Daiichi severe accident European Nuclear Safety Regulators Group (ENSREG) has highlighted the importance of safety re-assessment of NPP units and spent fuel storages in relation to external natural hazards and their combinations, with the purpose to improve severe accident management capabilities. To assist the State Nuclear Regulatory Inspectorate of Ukraine (SNRIU) in preparation of means for Severe Accident Management Guidelines (SAMG) validation the project financed by the European Commission through the Instrument for Nuclear Safety Cooperation (INSC) Action Programme 2015 has been performed in 2017 – 2021. The beneficiary organisation was SNRIU, the project team, led by Lithuanian Energy Institute (LEI) Lithuania, consists of experts from Gesellschaft für Anlagen- und Reaktorsicherheit (GRS) GmbH, Germany; Institute for Nuclear Safety and Radiation Protection (IRSN), France; Technical Safety Organisation of Belgium (BEL-V), Belgium; Technical Safety Organisation of Slovakia (VUJE), Slovakia and contractor experts in Ukraine State Nuclear Regulatory Inspectorate of Ukraine (SNRIU). The activities were performed within the frame of four tasks, covering: (1) the familiarization with the results of European studies in modelling of Fukushima Daiichi accident and activities on validation of calculation codes and models; (2) analysis of the existing severe accident models in Ukraine and improvement of their robustness; (3) development and validation of calculation models for the analysis of severe accidents progression in Spent Fuel Pool (SFP); and (4) enhancement of the previously developed models with the real safety improvements measures on severe accident management, already implemented at NPPs of Ukraine. The main goal was the development and validation of VVER-1000 models for Ukrainian NPP using MELCOR code by Ukrainian technical support organisation.

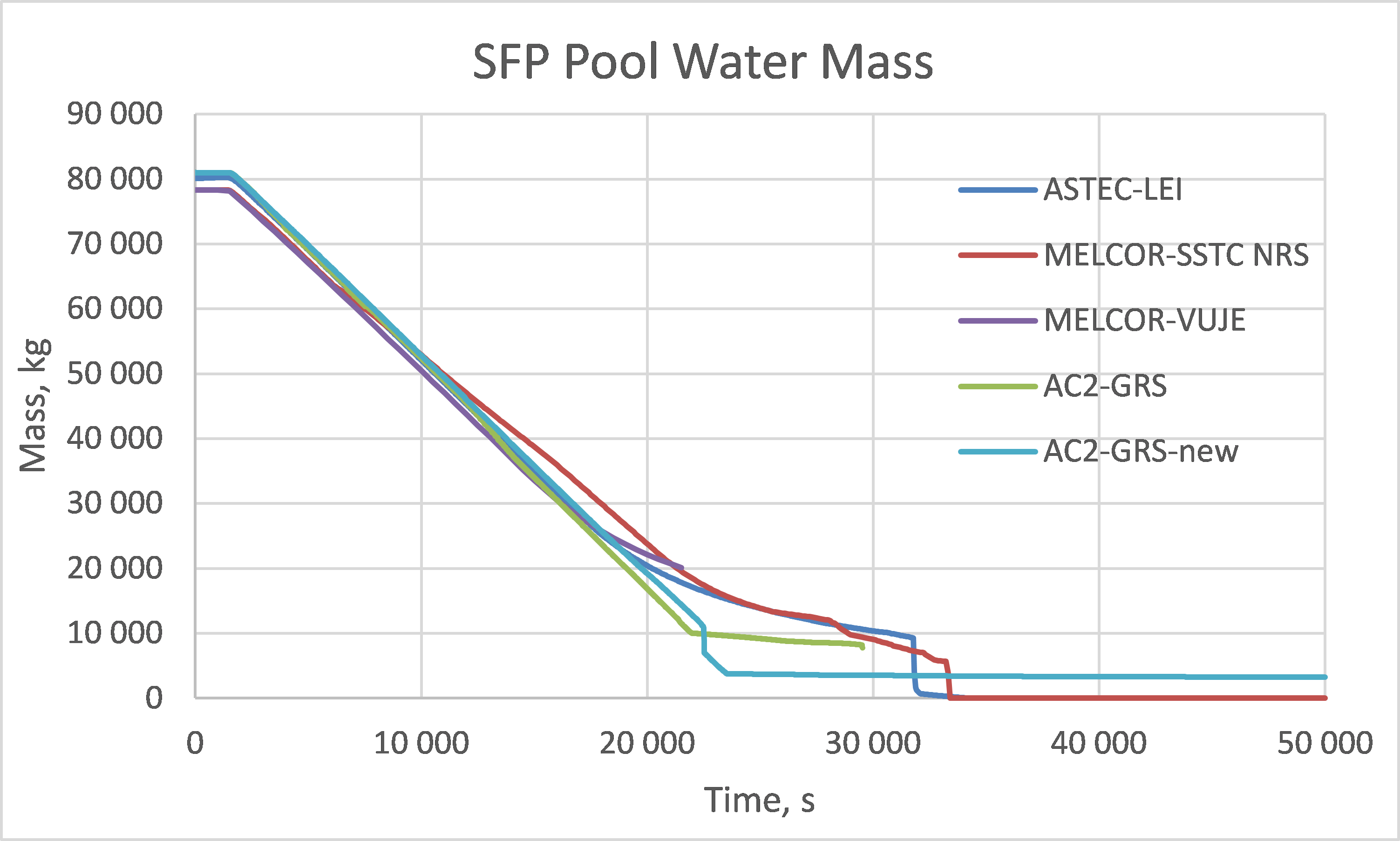

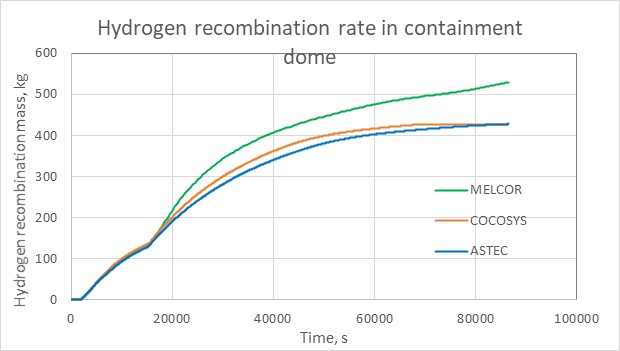

Within the frame of this project, the models of SFPs and containment for severe accident analysis in VVER-1000 were developed by all participating organisations using different computer codes. Due to the lack of relevant experiments in integral test facilities regarding severe accident scenarios in VVER-1000, the code-to-code comparison exercise (benchmarking) was chosen as a method for evaluation of developed models suitability. Two cases for the benchmarking were selected: (1) the SFP cooling failure (due to station blackout) during “emergency reloading” (fully unloaded reactor core to SFP 10 days after reactor emergency shutdown); (2) one-sided cold leg break and simultaneous total station blackout. SSTC NRS experts performed modelling of VVER-1000 reactor, SFP and containment using the MELCOR code, while GRS used ATHLET-CD for SFP and COCOSYS for containment modelling, LEI and IRSN used ASTEC and VUJE – MELCOR codes. The main conclusions from code – to – code comparison are:

- the VVER-1000 input deck (reactor, SFP and containment), developed by SSTC NRS experts using MELCOR code predicts qualitatively and quantitatively almost all severe accident phenomena;

- for some phenomena (water in SFP heat-up and boiling, spent fuel assemblies heat-up) the excellent agreement reached;

- for zirconium oxidation, fuel melting, dissolution, melt relocation, melt oxidation, quenching and shattering of Zirconium oxide there are a bigger scatter of calculation results in different codes calculations. For these phenomena, the MELCOR (SSTC NRS) code predicts qualitatively, but not quantitatively all phenomena. This means the reasonable agreement of code calculation;

- for pressure and temperature behaviour in containment there is a reasonable agreement of MELCOR code calculation because COCOSYS and ASTEC calculations show higher pressure in containment and faster pressure increase;

- for the release of gases through filtered containment venting systems and hydrogen recombination a good agreement with MELCOR code calculation was reached. Identified deviations in the long-term pressure build-up influencing both processes are the main difference in the benchmark results;

- for mixing of gases in containment the reasonable agreement with MELCOR code calculation was reached, because the ASTEC and COCOSYS calculations show the more homogenous distribution of steam in all containment, comparing to MELCOR calculation.

Thus, the results of performed benchmarks justify the suitability of the developed models and support the MELCOR input model applied by SSTC NRS in their independent confirmation calculations for Ukrainian NPPs.

|

|

Algirdas Kaliatka

Lithuanian Energy Institute

Algirdas.Kaliatka@lei.lt