Unreliability of reactor water level measurement during a severe accident

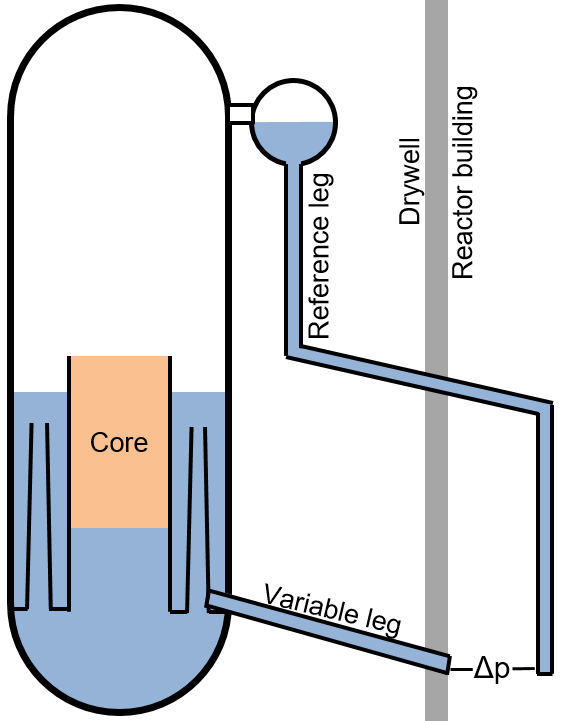

The reactor water level in BWRs is commonly measured with a system that is based on measuring the pressure difference between two water-filled pipes that are connected to the reactor at different elevations. During the Fukushima accident, the measurements were distorted by boiling of the water in the measurement system. VTT analyzed the phenomenon at Fukushima unit 2 with the MELCOR code. The measurement system was added to the MELCOR model, and boiling in the reference leg and variable leg was calculated with the code.

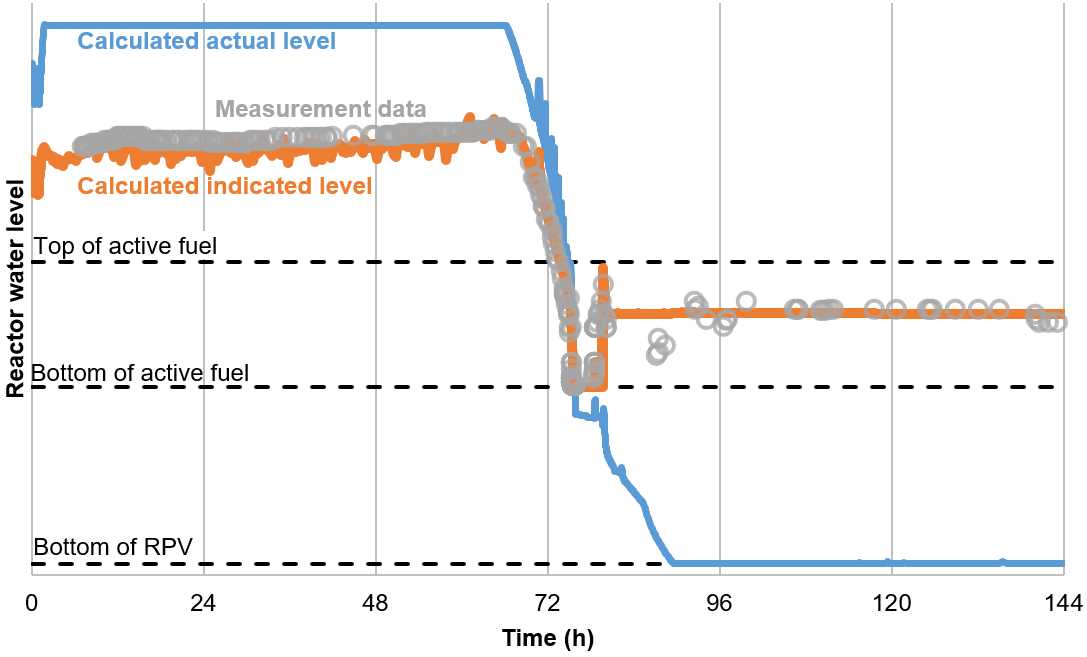

During the first 67 hours of the accident, the reactor was cooled with the RCIC system, and the water level in the reactor was above the measurement range. During the core uncovery, the measurements corresponded well to the actual level. However, at 78.5 h, the measured water level jumped to the middle of the core and remained there for several days. The Japanese accident investigation committee (ICANPS) suspected that the rise of the indicated level was caused by a leak of superheated steam from the reactor to the containment drywell, causing evaporation of the water in the measurement system. VTT's calculations support this hypothesis. The indicated water level could be reproduced by assuming a small leak from the steam line to the drywell, starting at 78.5 h. The results were published in the Nuclear Engineering and Design journal (https://doi.org/10.1016/j.nucengdes.2020.110760).

Measured water level during the Fukushima unit 2 accident, compared with the calculation © VTT

The reliability of the water level measurement could be improved by installing thermal insulation around the pipes of the measurement system. Another method to avoid the measurement errors would be minimizing the vertical part of the reference leg and the variable leg in the drywell. The pipes should penetrate the drywell wall at about the same elevation, at which they are connected to the reactor.

Tuomo Sevón

VTT

tuomo.sevon@vtt.fi