THELMA laboratory at the JSI

Accurate prediction of the convective single- and two-phase heat transfer is very important in process and power engineering for safety, reliability, and efficiency. In this aspect, boiling is particularly interesting and complex phenomena, which may significantly enhance the heat transfer from the heated surface to the coolant flow. The detailed understanding of these phenomena is of great importance and, as such, is put under investigation in the THELMA laboratory (Thermal-Hydraulics Experimental Laboratory for Multiphase Applications) at the Reactor Engineering Division at Jožef Stefan Institute (Slovenia) – https://r4.ijs.si/Thelma-e.

Recently started experimental campaigns include:

Flow-boiling experiment

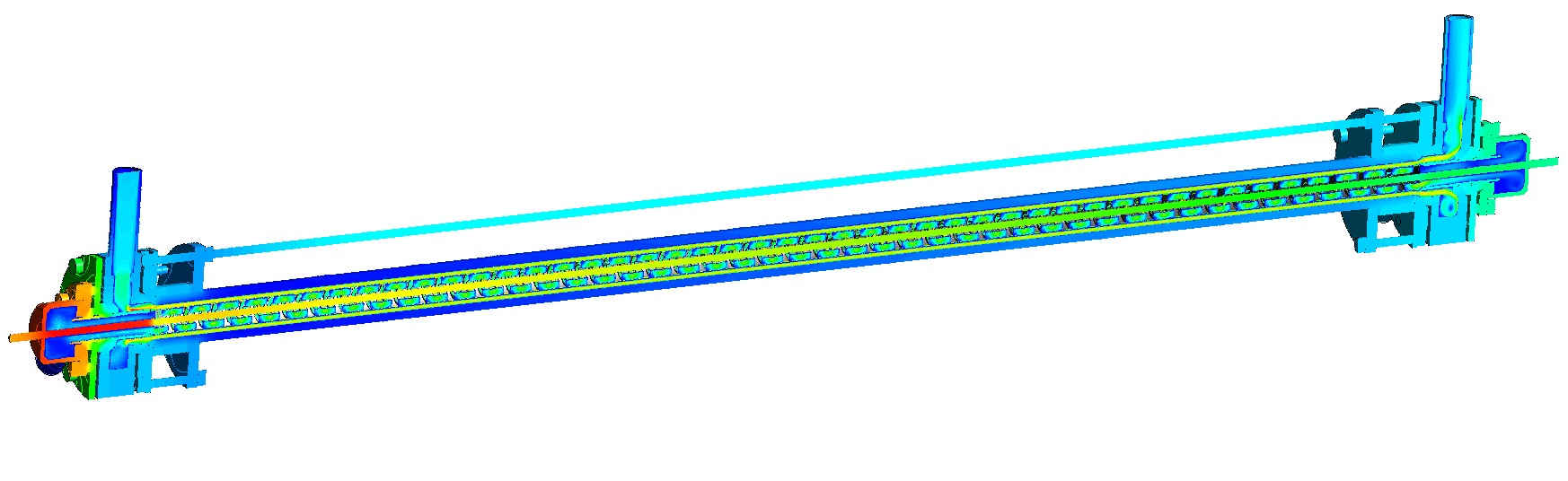

The main facility is a unique test loop designed for local heat flux measurement in annulus geometry, which resembles a single fuel rod in the light water reactors - see Figure 1. The applied design allows visual observations of various boiling regimes and establishment of temperature controlled environment at critical heat flux (CHF) conditions.

Taylor bubble experiment

Taylor bubble is a bullet-shaped bubble, which resides in a vertical pipe and occupies almost the entire cross section of the pipe (Figure 2 left). In practical situations, the Taylor bubble is frequently followed by other Taylor bubbles, which are separated from each other by liquid slugs. Such flow is commonly denoted as slug flow and can be found in numerous industrial applications, for example production of steam in geothermal power plants, boiling and condensation in thermal power plants, emergency core cooling of nuclear reactors, etc.

In our experiment, behaviour of the Taylor bubble is studied for water-air fluid mixture, which is characterized with a sharply curved interface at the trailing edge of the bubble (Figure 2). It has been observed that the Taylor bubble disintegrates (i.e. decays in size) when it is exposed to turbulent water flow. Accurate measurement of the bubble decay rate requires balanced buoyancy of the bubble by the opposing water flow. This is so-called counter-current flow regime. PIV measurements of the velocity field together with the measured bubble decay rate are of paramount importance for validation and development of new models for high-fidelity numerical simulations.

Thermal fluctuations in turbulent flow

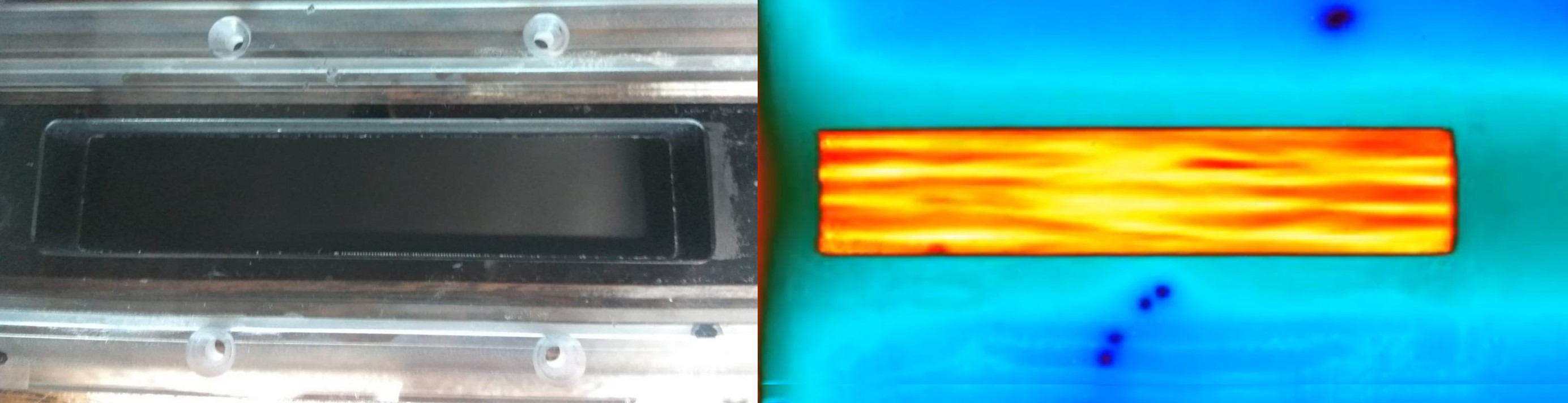

Conjugate heat transfer in single- and two-phase fluid flow is widely encountered in day to day life and has a paramount industrial and safety importance. In the view of this, a new experimental facility has been designed for investigation of temperature fluctuations on a heated foil, which is cooled with adjacent turbulent flow in square duct channel. Figure 3 shows an image of the heated foil in optical and IR light taken with the fast-speed cameras. An interesting temperature patterns is observed at the surface of the heated foil. In single phase flow, the so-called thermal streaks are observed, which are footprints of the coherent structures transported in the turbulent flow.

Blaž Mikuž

Jožef Stefan Institute

blaz.mikuz@ijs.si