Uncertainty and Sensitivity analysis of the QUENCH-06 Experiment by means of the ASTEC/RAVEN coupling

In the framework of the IAEA CRP “Advancing the State-of-Practice in Uncertainty and Sensitivity Methodologies for Severe Accident Analysis in Water Cooled Reactors (I31033)” an uncertainty quantification exercise, hosted by KIT, is currently under development based on test-6 of the QUENCH experimental facility, operating at KIT (Germany), and ENEA is participating. The test purpose is to characterize the behavior of nuclear fuel under oxidizing and quenching conditions. The test-6 experiment, performed in December 2000, feature 3 main phenomenological phases: a pre-oxidation phase; a heat-up phase, and a quenching phase.

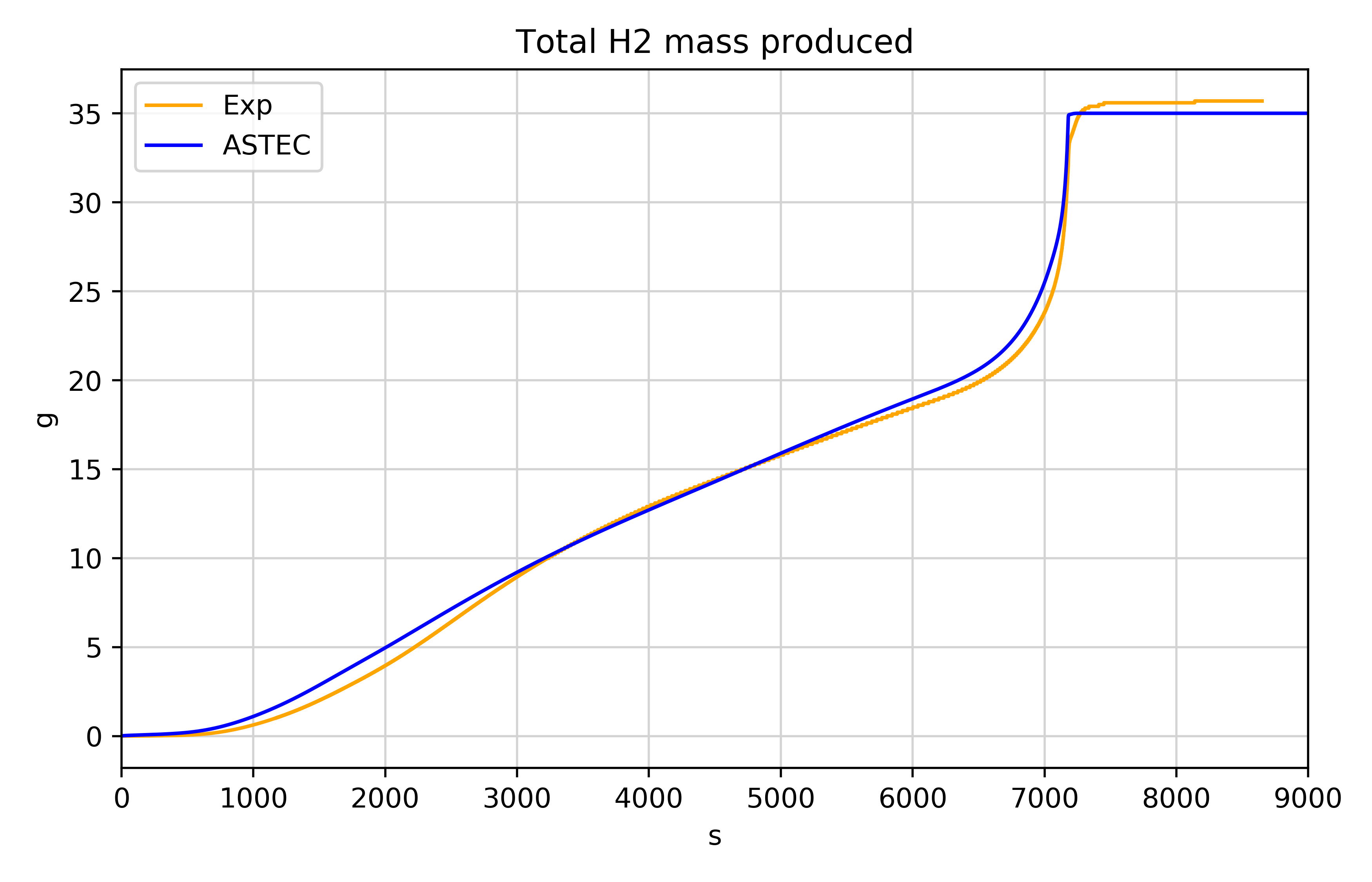

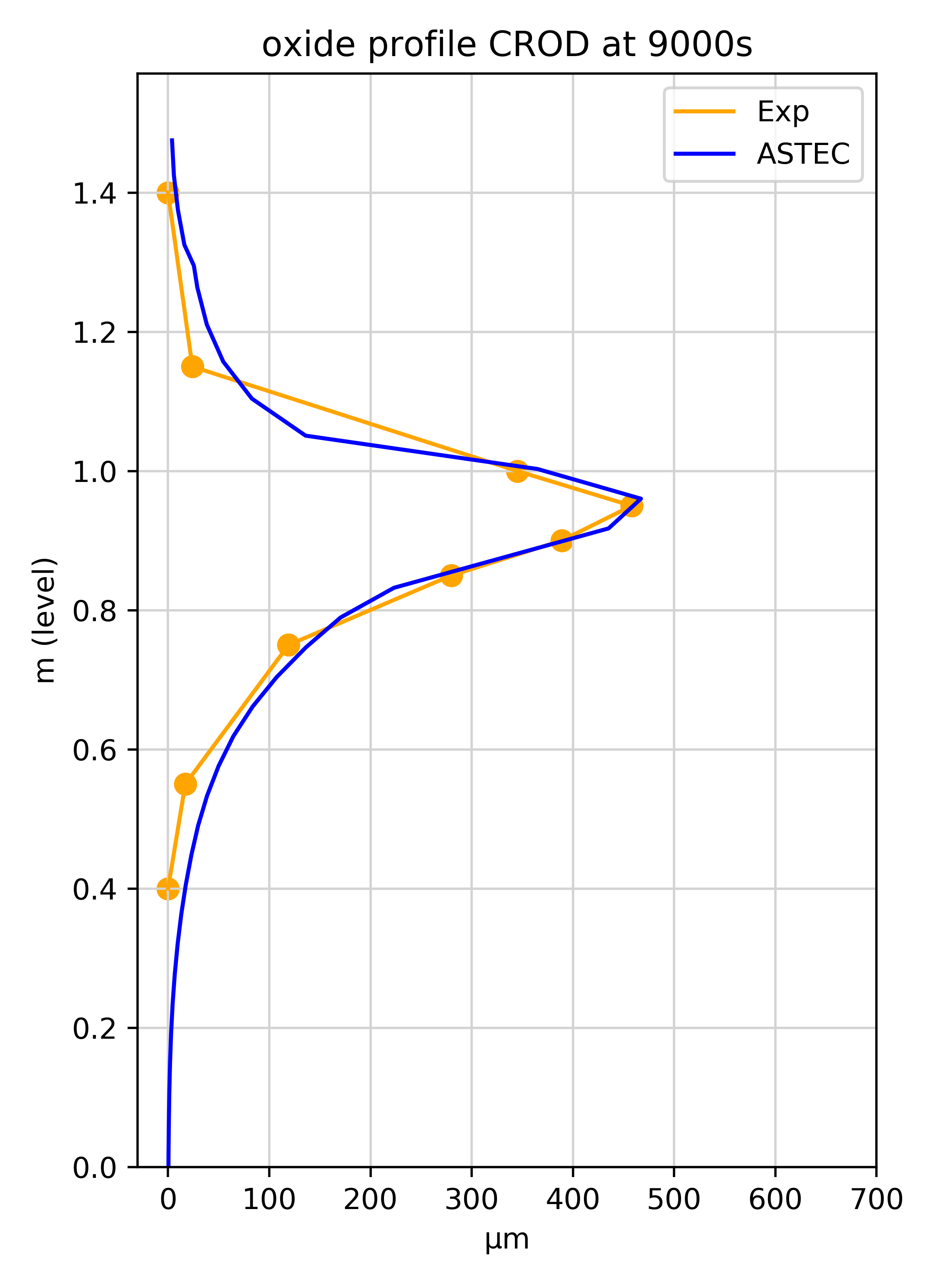

An ASTEC model of the QUENCH facility has been developed with the CESAR and ICARE modules of ASTEC (Study carried out with ASTEC V2, IRSN all rights reserved, [2020]). The analyses of the calculated data shows that the code is able to simulate the main phenomena of the experiment. The results of the ASTEC reference simulation of the test-6 experiment have been compared with the experimental data focusing the attention on selected figures of merit: cumulated hydrogen mass production (Figure 1); rods cladding and shroud temperatures as 950mm; water level in the bundle; shrouds, cladding, and corner rod oxidation profiles (Figure 2).

|

|

The qualitative and quantitative accuracy of the code have been evaluated. In order evaluate the accuracy of the code prediction, a Fast Fourier Transform Based Method has been used adopting the JSI FFTBM Add-In 2007 developed at Jožef Stefan Institute (Slovenia). As a result of the analysis, the code accuracy has been classified as very good for almost all the main figures of merits.

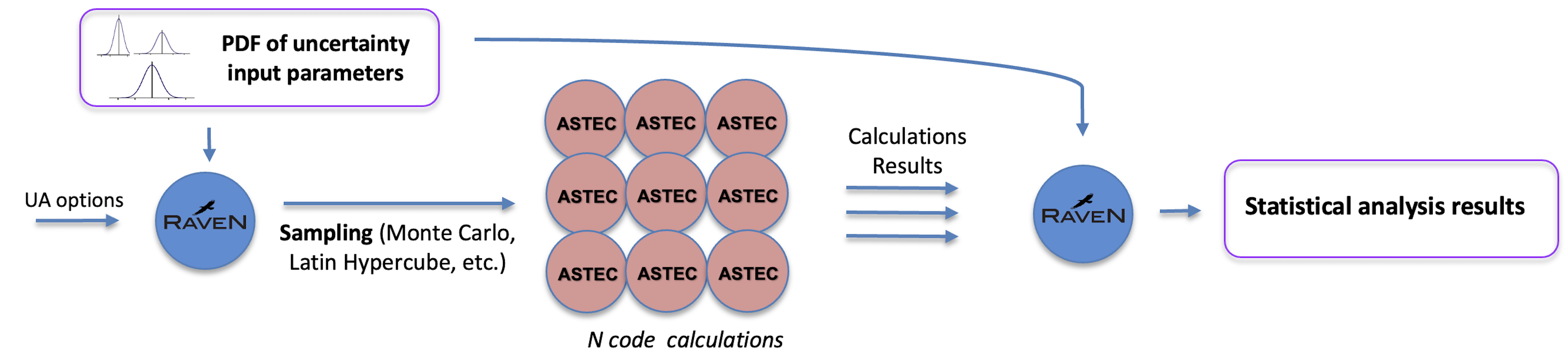

Finally, a preliminary uncertainty analysis is in progress through the ASTEC code coupled with the RAVEN tool, Figure 3, applying the probabilistic propagation of input uncertainties method. 22 input uncertain parameters have been selected and the cumulated hydrogen mass has been used as figure of merit of the uncertainty analyses. The analyses of the correlation coefficients suggest a significant correlation with two boundary condition parameters: the steam mass flow rate and the electric power. Further analyses are in progress to characterize the dispersion band of the results.

This research is supported by the International Atomic Energy Agency under the Coordinated Research Project award I31033 on Advancing the State-of-Practice in Uncertainty and Sensitivity Methodologies for Severe AccidentAnalysis in Water Cooled Reactors”, launched in 2019.

Fulvio Mascari

ENEA

fulvio.mascari@enea.it