The SF² project, for a safe interim storage of spent fuel

Currently it is legally foreseen that all 7 Belgian reactor units will definitively shut down between 2022 and 2025. The actual interim storage capacity for spent fuel is not sufficient to start the dismantling of those reactor units. This is the case on both the Doel and Tihange sites. Consequently, the construction of a supplementary interim storage capacity for spent fuel at both sites is necessary. This new storage capacity is provided through the SF² (Spent Fuel Storage Facility) project.

After weighing up the pros and cons, the option of dry storage in dual purpose casks was chosen by the licensee. The casks that will be stored in the main building are designed and manufactured by ORANO NPS (TN®24 casks) and GNS (CASTOR® casks) (Figure 1). The casks are of type B(U)F according to the classification of IAEA SSR-6. These casks are both used for the transport and storage of the spent fuel assemblies. The expected storage period is 80 years, considering the planning of the Belgian nuclear waste management authority (ONDRAF-NIRAS) for future geological disposal of the spent fuel and the conditioning of the spent fuel before its final disposal.

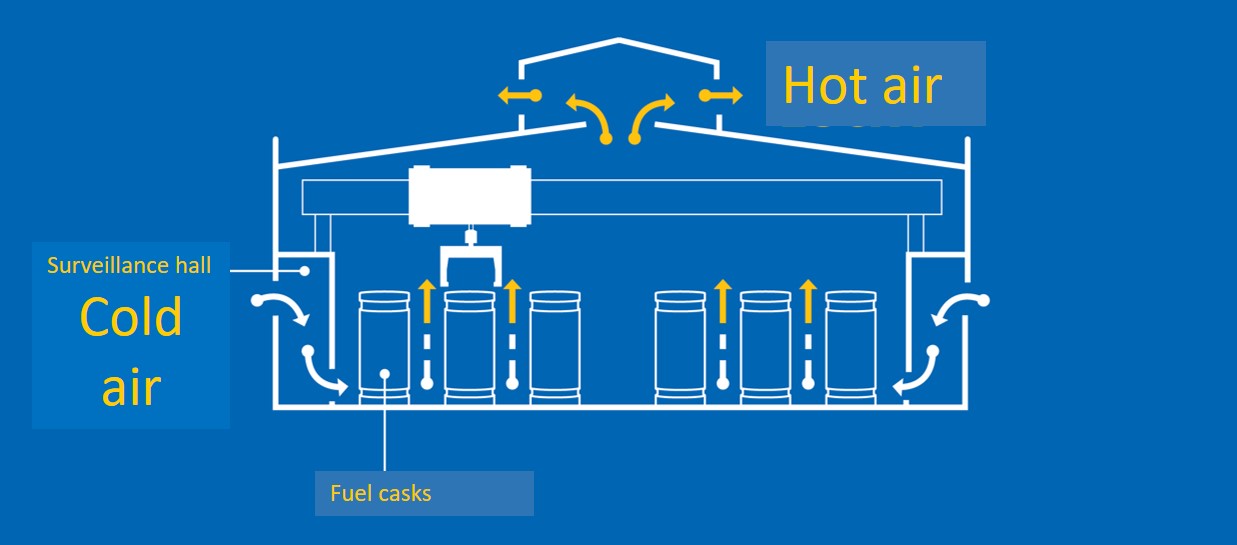

Safety functions (maintenance of sub-criticality, containment of radioactive materials, evacuation of residual power, radiological protection against ionizing radiation from the fuel and retrievability of the casks) are mainly fulfilled by the casks, the buildings (radiological protection, evacuation of the residual power) and associated equipment (bridge crane for retrievability of the casks) also participate.

The principle of natural convection has been chosen for the cooling of the casks (Figure 2).

For Tihange, the license request was submitted in May 2018. An analysis of the safety analysis reports was carried out by Bel V. Emphasis was placed on a number of topics:

- The thermal analysis. An important element was the clear specification of the operating conditions of storage in terms of expected thermal load, maximum authorized thermal load, in particular according to the type of cask considered, the mesh of the storage network and the position of the casks.

- The long term strategy. As the building is designed for 80 years, during that timeframe there should always be the possibility to unload a cask, to recover the nuclear fuel and possibly to repack it, and to carry out repairs if necessary.

- The civil engineering of the building. The assessment by Bel V allowed to ensure the civil engineering design provisions of the storage as well as the reasonably conservative nature of its sizing.

- Life time of the casks. Bel V drew licensee's attention to the importance of the cask aging program. In particular, an important element for the lifetime of the casks is the possible degradation of the resins.

- Approach for external events. Bel V stressed the importance of using a graded approach for events of external origin which respects the philosophy of the related safety demonstration guidances developed by the Federal Agency for the Nuclear Control (FANC).

Meanwhile, the licensing process was finished for the Tihange site and the license was granted on January 26, 2020. Construction works are currently ongoing on the Tihange site (Figure 3).

Bel V performs a follow-up of the construction. Several hold- and witnesspoints have been fixed by the regulatory body (FANC and Bel V) and, before introduction of spent fuel in the building, an entrance control program should been established, which includes conformity criteria that the spent fuel and the casks must meet and which are based at least on requirements for handling, transport and storage, including those related to their retrievability or transportability after the storage period.

The first casks are expected to be received in the building by the end of 2023.

For Doel, the license request was submitted in January 2020. The licensing process is still ongoing and Bel V focuses in its analysis on the major differences with Tihange's file:

- The thermal analysis where a higher thermal load is expected for the casks due to less years of cooling of the spent fuel in the wet storage pools and the presence of MOX fuel. There is also MOX fuel present at the Tihange site, however this fuel will be stored in the already existing wet storage facility.

- The different spent fuel characteristics require a thorough evaluation of their impact on the integrity of the fuel cladding during storage and the possibility of manipulation of the fuel after storage.

- Based on the meteorological data at the Doel site, a higher maximum ambient temperature (accidental condition) should be taken into account.

Currently, a Q&A process between the licensee and the regulatory body (FANC & Bel V) is ongoing about the abovementioned topics. It is expected to deliver the license in the spring this year and to introduce the first casks in the building by 2025.

Kurt Couckuyt

Bel V

kurt.couckuyt@belv.be

Sofie Vermote

Bel V

sofie.vermote@belv.be