Research for safety of future fusion power plant DEMO

According to the European Research Roadmap to the Realisation of Fusion Energy the next step after ITER facility is DEMO, the demonstration power plant. At present DEMO is coming to an end of pre-conceptual design phase and analyses on systems and components are being performed. These analyses provide an overview of DEMO integrated performance and capability to achieve expected targets while keeping in a safe operation domain. In the frames of EUROfusion project Lithuanian Energy Institute is involved in several tasks linked with DEMO safety assessment.

To identify the main accident scenarios that would need to be further analysed using deterministic methods the Functional Failure Mode and Effect Analysis (FFMEA) was performed for divertor and balance of plant systems of two blankets types – HCLL (Helium Cooled Lithium Lead) and DCLL (Dual Coolant Lithium Lead). As well FFMEA was developed for breeding system, thermal shields and cryostat system for DEMO with HCLL blanket.

Together with colleagues from Karlsruhe Institute of Technology and ENEA the review of computer codes used for safety assessment of fusion facilities was performed and the needs for further developments were identified. The main computer code for safety analysis remains MELCOR 1.8.6 with specific fusion extensions included. At the same time European computer code ASTEC is being developed at IRSN taking into account features necessary for fusion applications. A comprehensive review of accidents analyses was performed to collect the data and identify the needs for further analysis when DEMO conceptual design is developed.

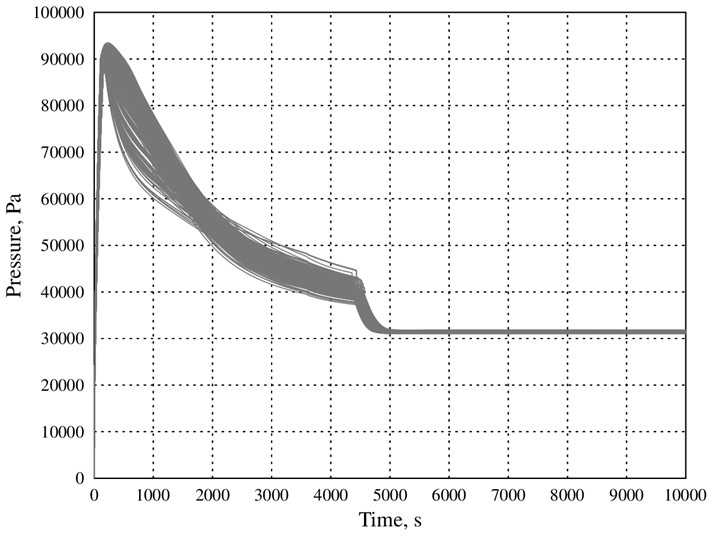

Loss-of-coolant-accident (LOCA) in DEMO divertor cooling system was analysed using computer code ASTEC. The performed analysis showed that overpressure of the vacuum vessel is prevented by the in-stalled protection system, and suggested that the safety valves are needed to install on the divertor cooling system to isolate the ruptured pipe and terminate the coolant release to the vacuum vessel. Methodology for sensitivity and uncertainty analysis for fusion facilities was developed. Sensitivity and uncertainty analysis for DEMO divertor LOCA was performed using SUNSET tool of computer code ASTEC.

The calculations for Water Cooled Lithium Lead breeder blanket module activation and decay heat production were performed. Comparative analyses for other European DEMO breeder blanket module concepts such as Dual Coolant Lithium Lead and Helium Cooled Lithium Lead and Helium Cooled Pebble Bed were also accomplished. A wide range of after irradiation cooling intervals were analysed in accordance with the requirements of device operation, maintenance, final decommissioning and waste management, using MCNP5 and FISPACT codes. The data produced by LEI experts cover neutron generation from deuterium and tritium reactions in nuclear fusion devices and subsequent irradiation of surrounding structures. Obtained activation characteristics such as activities, decay heats and dose rates are significant for design, operation and nuclear safety of European nuclear fusion devices developed under JET, ITER and DEMO projects.

Egidijus Urbonavičius

Lithuanian Energy Institute

egidijus.urbonavicius@lei.lt