Researchers of EK assessed raw materials to be used in nuclear-grade concretes to reduce nuclear decommissioning costs

Concrete is a widely used building material that is a mixture of natural raw materials and – to a smaller extent – artificial additives. The raw materials and the mixing ratios determine the structural properties of the concrete, e.g. compressive strength, density, and aging properties.

The domestic relevance of the research is the construction of the new Paks II nuclear power plant, where the concrete structures are preferably to be made from domestic raw materials. Therefore it is necessary to establish competences in the development of concrete that has adequate radiation resistance and favorable aging and activation characteristics. One of the important contributions to this goal is the composition determination and experimental activation testing of concrete samples and their raw materials via neutron irradiation.

In addition to the established industrial standards, concrete to be used in nuclear technology has to meet additional requirements. Concrete structures next to the active zone of the reactor, for instance, have to withstand high neutron- and gamma dose rates and elevated temperature for decades, while preserving its mechanical integrity and keeping the neutron-induced activation as low and as transient as reasonably achievable, i.e. the neutron-irradiation produces radioisotopes during the service life. Further, these concrete structures serve not only as structural components, but also as biological shielding, so the radiation-attenuation feature is also an important aspect.

The short- and medium-lived radioisotopes might affect the operation and maintenance routines, while the long-lived radionuclides can emit significant dose rates even after the shutdown. This has to be assessed in future decommissioning operations. For economic reasons, attempts shall be made to minimize the amount of radioactive waste. The future levels of radioactivity can be significantly influenced by the composition of the concrete, in particular with the levels of the trace contaminants introduced via the raw materials. So keeping the ALARA principle in mind, the best opportunity to take action is when the concrete is being manufactured. With careful selection of the raw materials, the difficulties and expenses during a future decommissioning can be reduced.

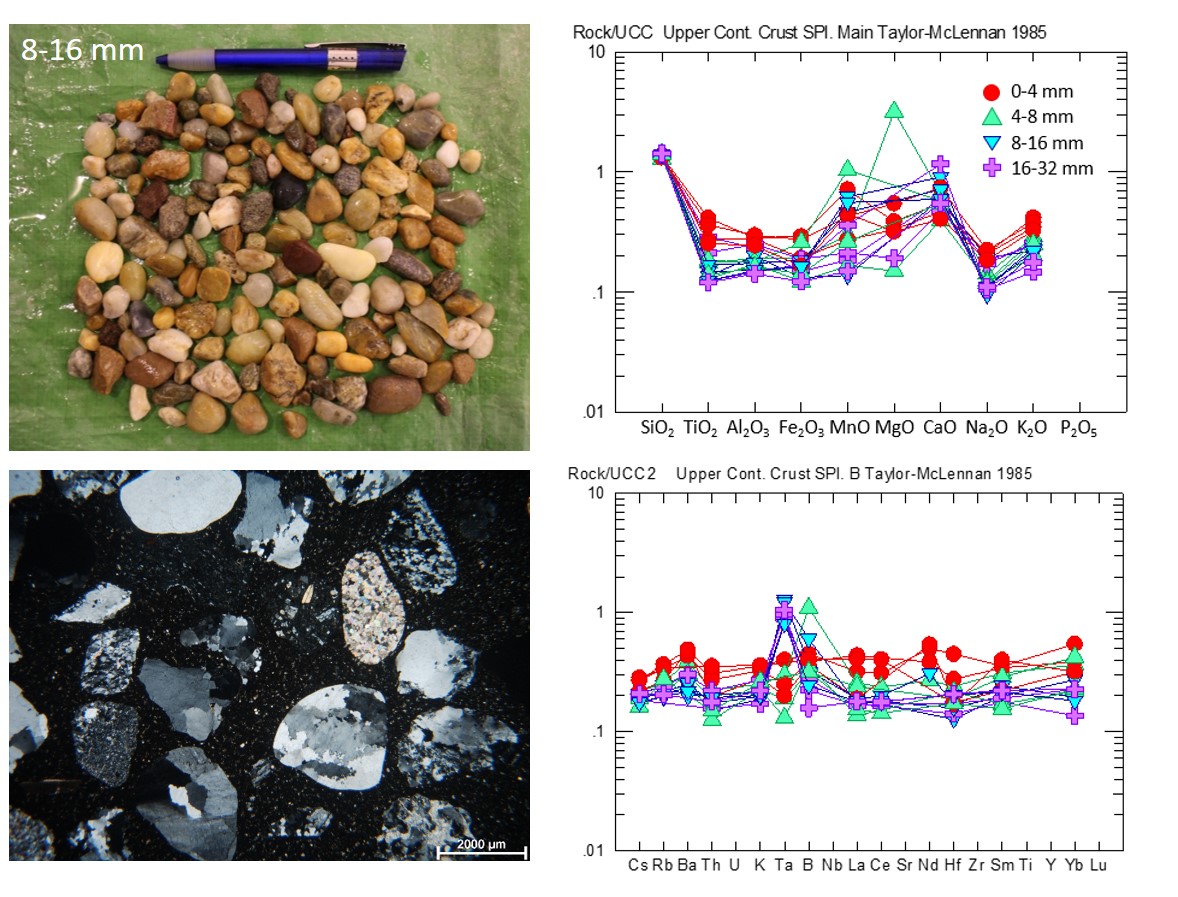

The EK research team has representatively sampled quarries at four large gravel mining regions in Hungary. The mineral compositions of pebble and sand types have been examined by optical microscopy, while the chemical compositions of the samples have been determined by nuclear analytical methods (instrumental neutron activation analysis: NAA, and prompt-gamma neutron activation analysis: PGAA). Nuclear analytical methods are the best choice for this exercise, as they are based on the nuclear reactions to which the concrete bodies will be exposed during operation, and instead of the elements, the relevant isotopes can be directly determined with high accuracy and high metrological quality.

The elemental analysis focused on the trace elements from which irradiation creates long-lived radioisotopes (141Ce, 60Co, 134Cs, 152Eu, 154Eu, 59Fe, 181Hf, 124Sb, 46Sc, 182Ta, 160Tb, 51Cr, 233Pa, 151Sm, 85Sr, and 65Zn) thus have importance in the activation of concrete around the reactor tank. The listed isotopes have significant radioactivity in the exposed concrete, even one year after the end of irradiation. Sand-gravel raw materials, in which the precursor elements are present in higher concentrations, are less suitable for nuclear applications.

Based on their analysis, a comprehensive raw material database was established. It was found that samples from different mines exhibit significantly different levels of impurities. On this basis, it is possible to identify the appropriate sources of adequate raw materials in Hungary, in which the amount of isotopes prone to activation is small, so that concrete with a low-activation tendency can be made from them.

László Szentmiklósi

Centre for Energy Research

laszlo.szentmiklosi@ek-cer.hu