Fine Reactivity Control at Reactor ALLEGRO

The enrichment, geometry and overall configuration of the gas-cooled ALLEGRO reactor core resulted in an undesirable effect in the form of significant changes in reactivity even with a small movement of the control rods. Consequently, new technical solution with steel half-cylinder device (HCD) was proposed.

ALLEGRO safety requirement: each of 3 control rod groups must be able to shut down reactor independently. Due to consequent high efficiency the control rod group, that regulates reactivity during cycle, was unable to regulate reactivity softly. Consequently, new technical solution with steel half-cylinder device (HCD) was proposed.

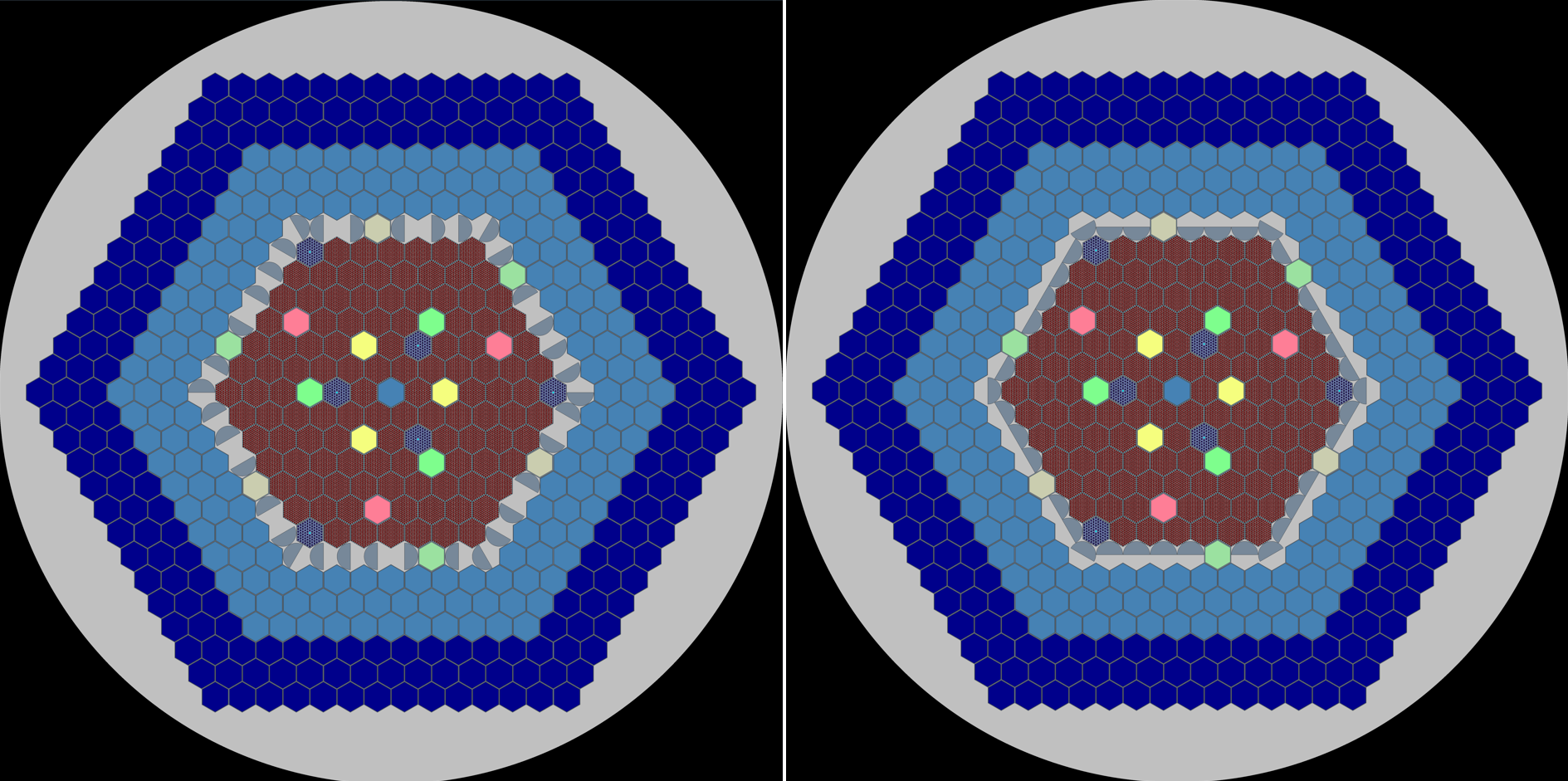

In first proposal half-cylinders are devices around the perimeter of the core in two circles. They are axially as high as the fuel and are homogeneously composed of steel. The principle of operation lies in their rotation around the axial axis which ends up in adjustment of radial neutron leakage.

At the beginning of the core cycle, it is assumed that the HCD is fully open. This position creates open channels around the core perimeter for the free escape of neutrons in the radial direction. The opened HCD position adjusts the escape of neutrons and the overall changes in the neutron flux. Cooperation of HCD with control rod group will result in more softer reactivity regulation - changes are no longer so significant as without HCD. At the beginning of the core cycle, there is fresh fuel in the core, which causes high neutron fluxes. It is compensated by higher radial leakage enabled by opened HCD. It is not the most convenient solution for neutron economy, with resulting shortening of the core cycle, but it is necessary from the point of view of safe core operation. Half-cylinders will be manipulated in cooperation with control rod group located on the core edge.

During the core cycle the fuel burning out will be compensated by gradual closure of HCD, the half-cylinders will be closed gradually in opposite directions, i.e. the one ring will rotate clockwise and other anticlockwise. This will have the effect of reducing size of the channels for neutron leakage. From a geometric point of view, it will increase amount of reflector material closer to the core around the circumference of the core. This should result in safe reactivity control using the control rod group together with the HCD. Even if they are completely closed and made of steel, the reflectivity efficiency will not be achieved as with reflector assemblies, since it is geometrically impossible to achieve the amount of material forming the HCD to be the same as the amount material forming the reflector assemblies. Therefore, even with complete closure, the amount of reflected neutrons is smaller than if there were reflector assemblies.

In the primary proposal, 2 main core designs were created – uranium oxide core and carbide core. Serious disadvantage of proposed change is very significant. It shortens the core cycle – 48 % for uranium oxide and 33 % for carbide core. Therefore, HCD were optimized just for one circle around the perimeter of the core, which should have the effect to extend the core cycle length. This optimization is currently under analyses.

Petr Darilek

Vuje

petr.darilek@vuje.sk

Marek Randik

Vuje

marek.randik@vuje.sk