Numerical simulation of shock absorber used for the safeguard of casks with spent fuel in case dropping

The Ignalina Nuclear Power Plant has two RBMK-1500 graphite-moderated boiling water channel type reactors. Both units currently are under active decommissioning process – Unit 1 since 2004 and Unit 2 - since 2009. Due to the absence of the possibility of spent nuclear fuel (SNF) transport for recycling, it was decided to store the SNF in a dry way using special casks. In the new build Interim Spent Fuel Storage Facility (ISFSF) the metal-concrete casks of new CONSTOR®RBMK1500/M2 type are used. Their operability and suitability have been demonstrated in the design documentation. The objective of a new ISFSF is to manage and temporary store spent nuclear fuel unloaded from the Ignalina NPP Units 1 and 2.

During the operation of Ignalina NPP, spent nuclear fuel was stored in the metal CASTOR®RBMK casks and reinforced concrete casks of CONSTOR®RBMK1500 type. In case, if one of these casks would lose its tightness, the reloading operation shall be performed in spent fuel storage compartments at Unit 1 or Unit 2. However, after dismantling of both Units the reloading of a damaged cask of any type will be possible only in the new ISFSF. During loading/unloading of the cask with spent fuel, the accident with the drop of a basket from a height up to 3.2 m onto a floor of the service room is possible. To reduce SNF cask failure risk in the ISFSF building areas, where SNF cask could be lifted more than 30 cm, special design shock absorbers are installed. The main function of these shock absorbers is to reduce the dynamic loads to a fully loaded SNF cask (weight 77 - 89 t) in case of dropping and prevent or minimise the possibility to lose the tightness of the SNF cask and release of radioactive materials from SNF rod(s).

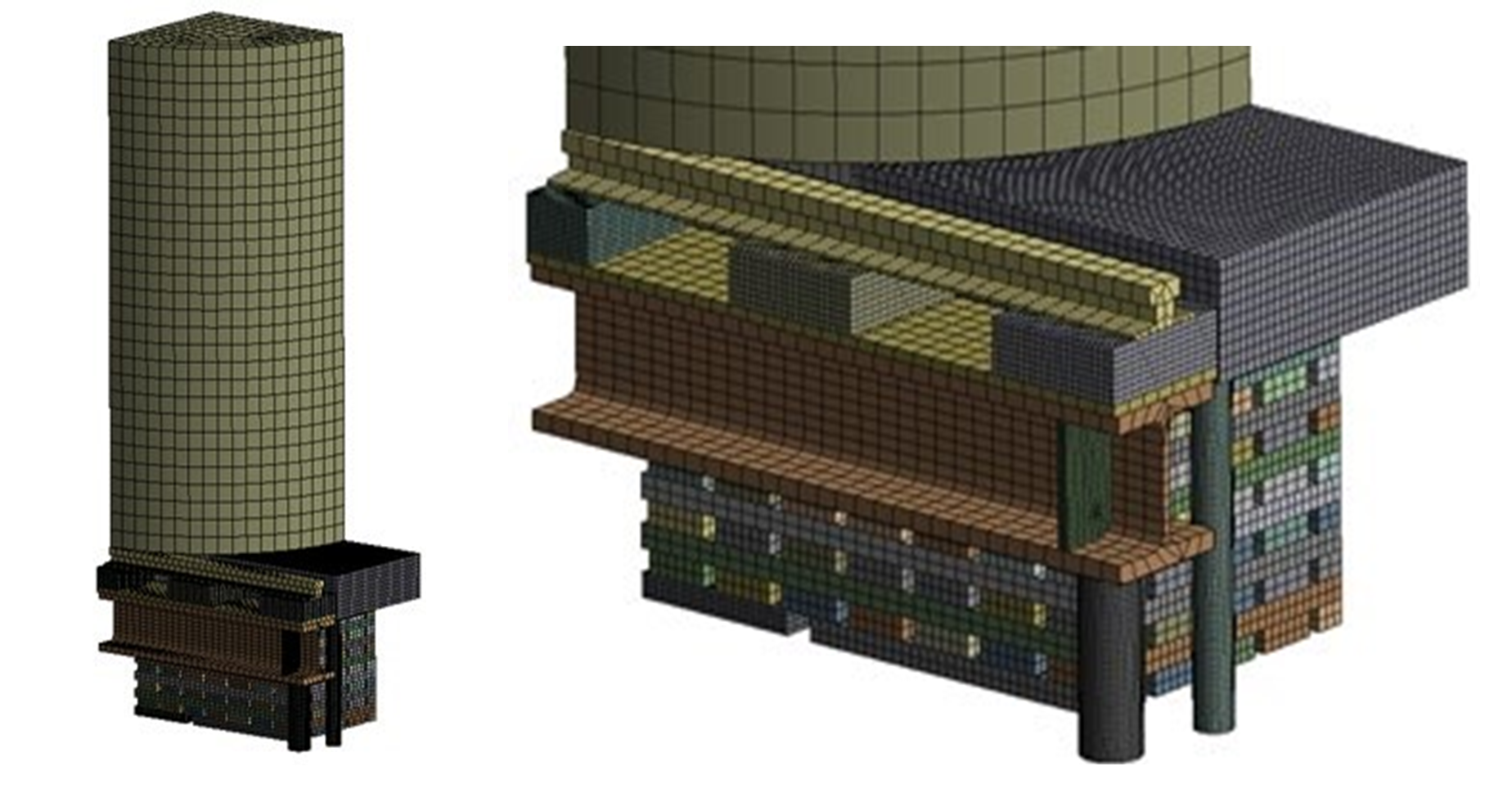

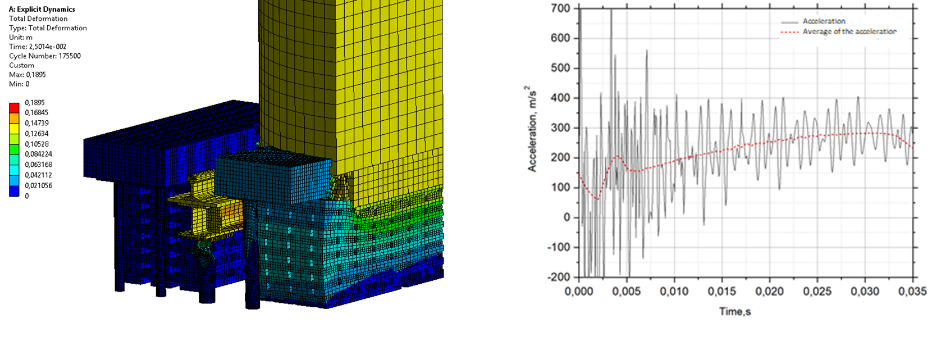

For evaluation of the shock absorbers capability to withstand the dynamic load in case of an accident, the dynamic analysis was performed. The acceptability of the shock absorber was estimated according to acceleration and displacement parameters. A validated finite element code ANSYS/Autodyn was used for numerical simulation of the shock absorber. An 8-node hexahedral element and only a quarter of the full geometry (because of symmetry) were used for the dynamic analysis performed.

The results of the analysis showed that the maximum acceleration of the CASTOR®RBMK cask (total weight ~77 t) during its impact on the shock absorber is 31.60 g, and in the case of the CONSTOR®RBMK-1500 cask (total weight ~89 t) - 29.56 g. Both results are well below the maximum design limit (85 g). This leads to the conclusion that all structural elements (spent fuel assembly, container) maintain their structural integrity even when in the case of cask dropping from the highest possible height.

|

|

Egidijus Babilas

Lithuanian Energy Institute

Egidijus.Babilas@lei.lt